Matsuoka, Tsuneyoshi

| Affiliation | Department of Mechanical Engineering |

|---|---|

| Title | Associate Professor |

| Fields of Research | Combustion engineering |

| Degree | D. Eng. (Hokkaido University) |

| Academic Societies | Combustion Society of Japan, The Japan Society of Mechanical Engineers, The Japanese Society for Experimental Mechanics, Japan Association for Fire Science and Engineering |

| matsuoka@me Please append ".tut.ac.jp" to the end of the address above. |

|

| Laboratory website URL | https://ece.me.tut.ac.jp/wp/ |

| Researcher information URL(researchmap) | Researcher information |

Research

- Pattern formation of solid combustion

- Development of new diagnostics of combustion system (Backlight CT; Peltier-type heat flux sensor; Ultrasonic levitation; etc...)

- Hybrid rocket motor

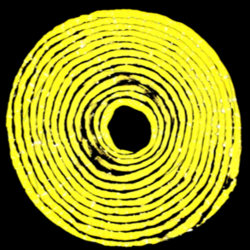

Theme1:Pattern formation of solid combustion

Overview

The depletion of fossil fuels resources has been a serous concern for a long time. Biomass such as wood, waste, sewage sludge and so on is expected as a promising resource to overcome the issue. However, the biomass commonly consist of various materials and its heat of combustion is usually low. Thus, it is quite difficult to effectively burn (use) the biomass as energy source. To take advantage of biomass effectively, a combustion technology which enables to adjust its performance in response to kinds of components is highly demanded. We focus on the oxygen-enhanced combustion as one of promising technologies.

There are many issues remained to realize the oxygen-enhanced combustion technology: one is to control the unstable behavior occurred near the limit condition. Recently we have developed an small wind tunnel facility which enables a precise control of flow and reaction of the burning area and successfully observed so-called fingering instability of flame spread over thermally-thick solid material (see the picture). Now we study the fingering instability to reveal the whole mechanism which allows us to control unstable behavior.

Selected publications and works

- Matsuoka, T., Yoshimasa, A., Masuda, M., and Nakamura, Y., "Study on Fingering Pattern of Spreading Flame Over Non-charring Solid in a Narrow Space", Fire Technology. [Epub ahead of print]

- Matsuoka, T., Murakami, S., Yamazaki, T., and Nakamura, Y., "Symmetric and Nonsymmetric Flame Spread between Parallel Plates of Thick Combustible Solid", Combustion Science and Technology. [Epub ahead of print]

- Fifteenth International Conference on Flow Dynamics (ICFD2018)@Sendai, Japan (2018.11.7-9) "Near-limit instabilities of opposed flame spread over thick solid combustibles". [invited talks]

- Matsuoka, T., Murakami, S., Yamazaki, T., and Nakamura, Y., "An appearance of asymmetrically spreading flames in narrow combustible channel", Transactions of the JSME (in Japanease), Vol.83 No.852 (2017), paper#: 17-00009.

- The Collaborative Research Symposium, Center for Mathematical Modeling and Applications (CMMA), Joint Usage / Research Center, Meiji University, Meiji Institute for Advanced Study of Mathematical Science (MIMS) "Mathematics of Instability in Fire" @Meiji University Nakano Campus (Tokyo, Japan) (2017.10.5) "Asymmetrically spreading flame in narrow channel".[invited talks]

- Matsuoka, T., Nakashima, K., Nakamura, Y., and Noda, S., "Appearance of Flamelets Spreading over Thermally Thick Fuel", Proc. Combust. Inst., Vol.36, issue 2 (2017), pp.3019-3026.

Keywords

Theme2:Diagnostics of combustion system (back-light CT method / heat flux sensor)

Overview

Understanding of the combustion characteristics of materials is of importance from a view point of fire safety. Generally, the combustion characteristics depends on shape and the shape deforms as time proceeds. Therefore, it is necessary to understand how the deformation proceeds during combustion for precise evaluation of the combustion characteristics. However, the effect of deformation has not been considered so far because it is quite difficult to visualize and measure the shape due to an existence of flame around the burning object. This study proposes and develops a new imaging system based on a combination techniques of backlighting photography and computed tomography. It enables in-situ visualization and measurement of 3D outer shape of burning thermoplastics.

Selected publications and works

- Matsuoka T., Kyogoku T., Koike Y., Terada H., Nakamura Y., "Time-series 3D Measurement of Outer Shape of Burning Thermoplastic", The Fifty-Sixth Symposium (Japanese) on Combustion, 2018.11 (Sakai), E333.

- Matsuoka T., Koike Y., Terada H., Nakamura Y., "Visualization of Burning Plastic by Image Reconstruction with Backlighting Photography", JAFSE Annual Symposium 2018, 2018.5 (Kitakyusyu), C-40, pp.310-311.

- Matsuoka T., Koike Y., Nakamura Y., "In-situ Extraction Method of Outer Surface Shape of Deforming Thermoplastic Materials during Combustion", Journal of JSEM, Vol.17 No.3 (2017), 191-197.

- Matsuoka T., Koike Y., Nakamura Y., "Reconstruction of Backlight Image for Visualization of Deformation Process of Burning Thermoplasctic", Journal of JSEM, National Conference of the Visualization Society of Japan (Muroran2017), 2017.11 (Muroran, Japan), OS6-3.

Keywords

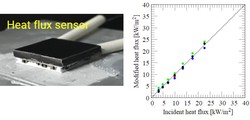

Theme3:Diagnostics of combustion system (heat flux sensor)

Overview

For measurement of heat flux in fire test, a sensor is required to be high-temperature resisted and to be perceivable to the heat from any directions. Hence, a so-called Schmidt-Boelter gauge or Gardon gauge, which commonly consists of thermopile(s) to generate a signal and its body is water-cooled, is preferred for fire test. However, the sensitivity and the responsibility depend on the sensor size and in addition, there is a trade-off relationship between them, indicating it is hard to be miniaturized. In addition, the water-cooled body unintentionally changes the temperature field around the sensor, which leads to experimental error. The above disadvantages become significant especially for small-scale fire test. For developing a better fire scenario, an accurate data is important to validate the model proposed and therefore, a small sensor with high sensitivity and responsibility is highly demanded to do so. To overcome the disadvantages of conventional heat flux sensors, we propose and develop a novel temperature-controlled heat flux sensor which is adjustable to the outlet heat flux to the inlet flux maintaining the temperature to the ambient.

Selected publications and works

- Matsugi D., Matsuoak T., Matsuyama K., Nakamura Y., "A constant-temperature heat flux sensor with heat feedback control", Thermal Engineering Conference 2018, 2018.10 (Toyama, Japan), B215

Keywords

Title of class

Applied Mathematics III (B3)

Experimental Practice for Mechanical Engineering (B3)

Research Project (B2)

Others (Awards, Committees, Board members)

[Awards]- Young Engineers Award of Tokai Branch of JSME, Tokai Branch of The Japan Society of Mechanical Engineers, 2019.3

- Young Researcher Encouragement Award, Combustion Society of Japan, 2018.11

- Outstanding reviewer, Proceedings of Combustion Institute, 2018.1

- Best Presentation Award of 2013 JSEM Annual Conference on Experimental Mechanics (T. Matsuoka, Y. Nakamura, H. Nagata, T. Yamazaki), The Japan Society for Experimental Mechanics, 2013.9

- Thermal Engineering Division, The Japan Society of Mechanical Engineers; Public Relations Committee

- Combustion Summer School, Combustion Society of Japan; Committee

- The Fifty-Seventh Symposium (Japanese) on Combustion (2019.11.20-22)@Sapporo, Japan; Executive Committee

- 97th Fluids Engineering Conference, The Japan Society of Mechanical Engineering (2019.11.7-8)@Toyohashi, Japan, Executive Committee

- 30th The Japan Society of Microgravity Application Conference (JASMAC-30) (2018.10.29-31)@Gifu, Japan; Executive Committee

- The 22nd National Symposium on Power and Energy Systems (2017.6.14-15)@Toyohashi, Japan; Executive Committee

- International Conference on Advanced Technology in Experimental Mechanics 2015 (ATEM'15) (2015.10.4-8)@LOISIR HOTEL TOYOHASHI (Toyohashi, Japan), Scientific Committee

- JSPS KAKENHI Early-Career Scientists, Instability of flame spread in narrow channel: critical condition and dynamic behavior (18K13967), 2018 - 2019.

- The TATEMATSU Foundation (Research grant), 3D visualization system for temporal deformation of burning materials, 2018.

- The Hibi Science Foundation (Research grant), Development of small heat flux sensor based on active control of outlet heat flux, 2018.

- The NAGAI Foundatino for Science & Technology (Exchange research grant), 2018.

- DAIKO Foundation (Exchange research grant), 2017.

- Collaborative Research in 2017, The Research Center for Fire Safety Science, Tokyo University of Science, Development of a novel heat flux sensor, 2017.

- JSPS KAKENHI Grant-in-Aid for Young Scientists (B), A critical condition for combustion mode transition of flame spread in narrow channel (16K16365), 2016-2017.

- SUZUKI Foundation (Exchange research grant), 2016.

- The Ogasawara Foundation for the Promotion of Science & Technology (Exchange research grant), 2014.

- The TATEMATSU Foundation (Research grant), Development of high-load combustion system of RDF using oxygen impinging jet, 2013.

- The Naito Science & Engineering Foundation (Research grant), Study on oxygen-enhanced combustion for development of high-efficiency waste-to-energy system, 2013.

- JSPS KAKENHI Grant-in-Aid for Research Activity start-up , Heat Transfer Mechanism of Solid Combustion by Mulitple Impinging Jets Involving both Flow and Reaction Field (24860002), 2012-2013.

- Yoshida Foundation for Science and Technology (Exchange research grant), 2012.

- JSPS, Grant-in-Aid for JSPS Fellows, Micro-flame spread over solid/liquid fuels (10J04074), 2010-2011.

- Hokkaido University Cooperative Pioneer Development System (Program for promoting career), 2009.12-2010.3

- Hokkaido University The Clark Memorial Foundation (Exchange research grant), 2009.

- Hokkaido University The Clark Memorial Foundation (Research grant for Ph.D. Student), Study on flame spread in narrow solid tube, 2008.