Takeichi, Yoshinori

| Affiliation | Department of Mechanical Engineering |

|---|---|

| Title | Associate Professor |

| Fields of Research | Tribology / Surface Analysis |

| Degree | Dr. Eng. (Nagoya Institute of Technology) |

| Academic Societies | Japanese Society of Tribologists / The Japan Society of Mechanical Engineers / The Japan Society of Applied Physics |

| takeichi@ Please append "tut.jp" to the end of the address above. |

|

| Laboratory website URL | http://tribo.me.tut.ac.jp |

| Researcher information URL(researchmap) | Researcher information |

Research

Tribology is an interdisciplinary field dealing with various scientific and technological problems related to keywords such as friction, wear and lubrication. Wear is often a problem where you do not usually see it, and tribology is playing a role "in the edge of the edge" in the industrial field.

1: Tribology of high temperature solid lubricating materials

- Research aimed at improving tribological characteristics of sliding materials and solid lubricants in high temperature atmosphere.

2: Tribology of polymeric materials

- Study aiming at elucidation of tribochemical reaction in friction of PTFE (polytetrafluoroethylene).

- Study on improvement of friction and wear characteristics of phenolic resin molding materials under high load sliding conditions.

3: Tribology of ball joint

- Study on performance improvement of ball joints for automobiles.

- Lubrication mechanism of grease in ball joint clarification.

Theme1:Tribology of High Temperature Solid Lubricant

Overview

Friction materials used in high temperature environments include special alloys and ceramics. Although research to obtain materials with excellent tribological properties has been conducted up to now, there are many problems such as cost problems and toughness problems.

On the other hand, lubrication by oil and grease is difficult in high temperature environment. Under high temperature circumstances, solid lubricants such as molybdenum disulfide and graphite are generally used, but lubricity is lost by oxidation from around 400 °C.

We aim to obtain a solid lubricant to be used in high temperature environment and are conducting research to clarify lubrication mechanism of solid lubricant under high temperature environment.

Theme2:Tribology of Polymer Materials

Overview

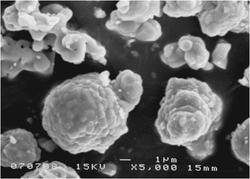

● PTFE (polytetrafluoroethylene)

PTFE (polytetrafluoroethylene) widely known as a trademark of "Teflon" exhibits excellent low friction characteristics among various plastic materials, however, it shows larger wear amount.

In this theme, we are studying PTFE from the following viewpoint.

- Improvement of wear resistance of PTFE by adding various fillers

- Understanding wear reduction mechanism of PTFE

- Understanding tribochemical reaction of metal surface by sliding with PTFE

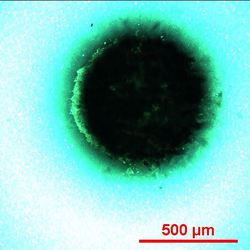

● Phenol resin

In the tribology field, phenolic resin is widely known as a binder of a brake material and is basically a material whose friction coefficient is not low.

Many sliding plastics are thermoplastic resins, and at parts where the sliding conditions are high loading, the resin material melts due to frictional heat and becomes unusable.

Under such conditions, sliding is often caused by metal materials and the like, but weight reduction can be achieved by using a phenolic resin as a sliding material.

In this theme, for the purpose of using phenolic resin for high load sliding parts, focusing on resin chemical reaction etc., we investigated the mechanism of improvement of wear resistance.

Keywords

Theme3:Tribology of Ball Joint

Overview

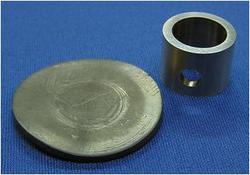

A ball joint is one of fitting part, which is structured to cover a metal ball in a ball shape with a resin sheet, and grease is supplied between the two materials.

Ball joints for automobiles are important security components and will be used under a wide range of temperature conditions, from use at extremely cold temperatures to use under high temperature environments around the engine.

Also, not the sliding motion in a certain direction, the friction direction always changes, and the amount of sliding is also often small, which is a severe usage as grease lubrication.

The aim of this theme is to obtain the knowledge that contributes to the more optimal design of the ball joint by improving the tribological characteristics of the ball joint and understanding the grease lubrication mechanism.

(Collaboration with SOMIC Ishikawa Co., Ltd.)

Keywords

Title of class

Surface Analysis / Tribology / Machine Design / Creative Experiment for Mechanical Engineering / Mechanics of Solids 2