ここからコンテンツです。

Utilizing FRPs in the construction and reinforcement of buildings and bridges

Yukihiro Matsumoto

Professor Yukihiro Matsumoto conducts research on fiber-reinforced plastics (FRPs), which are produced by moding carbon or glass fibers with resin. FRPs are lightweight and durable and have a high degree of freedom in their shape. They are widely used in airplanes and automobiles. Professor Matsumoto is exploring methodologies for utilizing the properties of FRPs in the construction and reinforcement of civil engineering structures such as buildings and bridges. What are the benefits of using FRPs as a material for construction and civil engineering?

Interview and report by Madoka Tainaka

FRPs exhibit both lightness and strength

FRPs were developed in the early 20th century and used partly as a structural material in lifeboats and fighter jets during wartime. At present, they are indispensable in manufacturing automobiles and in other aspects of our lives. However, in the late 20th century, FRPs started gaining attention as a material for building and civil engineering materials. Professor Matsumoto offers the following explanation as his reason behind researching FRPs, which are an uncommon material for construction and civil engineering.

"All materials have advantages and disadvantages, but the biggest advantage of FRPs is their lightness and strength. Furthermore, the main materials of FRP are originally fibers; therefore, they resemble a cloth before being molded with resin, giving them a very high degree of freedom in shape. Another advantage is that they do not corrode as steel does. Although FRPs have not yet become widespread in construction, I believe their unique features can be utilized in many situations."

The biggest significant disadvantage of using FRPs is that we do not yet fully understand these materials or the best way to design and use them. Professor Matsumoto indicates that applications of these materials in construction are not suitable for mass production, unlike with automobiles for example. In addition, we need to learn how to use the material characteristics to achieve maximum strength, which is all important for construction.

"FRPs are materials with variable qualities, and their strength changes depending on the direction of the fibers. The structural property of FRPs has two aspects. The tensile strength, which indicates if the material will tear when pulled, is undoubtedly stronger than that of steel. However, the rigidity, which indicates the extent of deformity when force is applied, is sometimes less than half that of steel. Certain buildings in the world, even in Japan, are made entirely from FRPs. However, realistically, instead of using only FRPs, I think combining them with steel, concrete, and other materials and finding the appropriate material and place to use them will be wiser."

Utilization for seismic reinforcement of joints and steel materials

Professor Matsumoto discusses the reinforcement of steel materials and their joints with carbon-fiber-reinforced plastics (CFRPs) as an example of the combination of FRPs and other materials.

"As you may have seen the brace members in factories, L-shaped components, known as angle irons, are installed diagonally and fastened with bolts to form part of the structure. However, with buildings that were built per old structural design standards, the force and strain of an earthquake on the building can weaken the strength of the bolt holes which will likely cause structural failure. To address this issue, various solutions have been developed and put into practical use, such as reinforcement through welding and additional bolts. However, in reality, limited progress has been made in reinforcement work because of issues at some factories, such as a reluctance to weld due to the risk of sparks, or an inability to shut down for several days for reinforcement work. Therefore, we developed a simple method for affixing the carbon fiber over the bolt, injecting it with resin, and hardening it while it adheres."

According to Professor Matsumoto, the advantage of this method is that no large-scale preparation is required, and there is no need to build scaffolding or carry heavy steel plates. "When we conducted the experiment in several locations, students were able to complete the task in approximately two hours using only a four-legged scaffolding stepladder." As mentioned earlier, FRPs can be wrapped around the shape of an object; therefore, they can be flexibly adapted on-site.

Professor Matsumoto also believes that there is considerable potential for increasing the all important strength of the material.

"In the experiments, we deformed the structure horizontally to simulate the horizontal shaking of an earthquake, but the bolt joints did not break even after moving about 120 mm. Without reinforcement, it would have broken at approximately 30 mm and lost its supporting power immediately. However, if reinforced with FRPs, it will continue to maintain its strength up to an extent even after 120 mm, and will not suddenly collapse. This toughness is not due to the strength of the carbon fibers but rather an inherent property of steel. In other words, supplementing the structure with FRPs at its weak points allows us to make the most of the inherent qualities of steel."

Understanding how to get the best out of the variable qualities of FRPs

Owing to their low weight, GFRP bridges using glass fibers have already been developed as pedestrian bridges. Professor Matsumoto however, advises caution when using these "quirky materials".

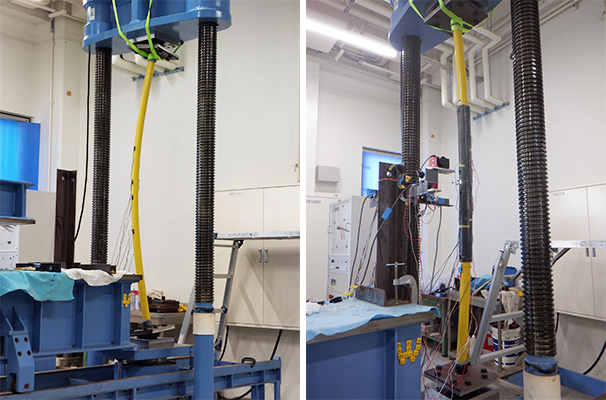

without strengthening (left) and with unbonded CFRP strengthening (right).

"In regular FRPs, most of the fibers are in the vertical direction (longitudinal direction). However, if a hole is made perpendicular to the fiber and hooked to a bolt, then that part may act as a trigger and cause the bolt to slide out. In other words, the weakness of FRP is that if used incorrectly, it loses its strength. Therefore, we proposed a method for increasing the strength by tilting the fibers at a 45° angle."

However, if special FRPs with tilted fibers are used in all locations, then productivity will drop and the unit cost of materials will substantially increase. Therefore, to maximize performance, Professor Matsumoto proposed a method for attaching the diagonal-fiber-containing materials only around the bolts.

"Simply affixing FRPs with 0.5-mm-thick fibers diagonally on both sides of a 6-mm-thick regular FRP more than doubles the yield strength. Moreover, even if the structure is broken by an unexpected force, it will not suddenly lose its strength and the diagonal fibers will not fall apart. I think that FRPs can be used most advantageously in situations that make the most of their low weight and strength, such as in seaside pedestrian bridges, which are susceptible to corrosion, bridges in locations where temporary construction using heavy machinery is difficult, and temporary bridges erected during a disaster."

Developing a simple method that does not require adhesives

When reinforcing with FRPs, another drawback is affixing the fibers with adhesives. The performance of FRPs deteriorates if the adhesive peels off. Professor Matsumoto was working on the use of optical fiber sensors for detecting signs of adhesive peeling. However, he realized that there was no need to worry about the adhesives peeling off if no adheres were used. Therefore, he is currently investigating a method for maximizing the material performance without using adhesives.

"Roofs can be made of slender steel pipes, such as the steel three-dimensional truss structure (space frame) used for the festival plaza at the 1970 Osaka Expo. However, if an unexpected force greater than the design force is applied, such a roof might break. To reinforce it, we developed an extremely simple method of wrapping CFRPs around the center of the steel material."

The work is remarkably simple: similar to a plaster cast, the CFRP is fitted like a plaster cast to match the shape of the steel. Furthermore, Professor Matsumoto said that they succeeded in increasing the yield strength of the steel material by 20–30%. CFRPs are light; therefore, the weight increase can be minimized on the structure.

"Even if a compressive force is applied on the column, the CFRP-reinforced parts will not deform, as opposed to the unreinforced parts. This procedure involves covering the material with a semicircular pipe-shaped CFRP, which makes working on roofs very easy. Although the high material costs of the CFRPs themselves are unavoidable, the lightweight nature of these materials renders additional expenses such as a crane or scaffolding unnecessary, as well as not requiring advanced techniques. Therefore, overall, CFRPs can be considered to be more efficient and economical than other reinforcement materials. Moreover, Japanese manufacturers lead the CFRP market as they own the top three carbon fiber manufacturers. Furthermore, I think that the integration of construction technology with Japan’s material technology is also an advantage."

Seismic reinforcement of factories and buildings built as per old structural design standards is an urgent issue in Japan, a country prone to major earthquakes. We look forward to the widespread use of the simple seismic reinforcement using FRP developed by Professor Matsumoto and his team.

Reporter's Note

Professor Matsumoto says that he loved playing in the garden since he was a child, making all kinds of things with his hands using garden plants and soil. He wanted to work in building structures; thus, he studied at the Department of Architecture in the National Institute of Technology, Yonago College, and then progressed to the Toyohashi University of Technology.

"Perhaps because of the thriving automobile industry in the Tokai region, I had many opportunities to work with FRPs at the university, and I soon became an expert in FRPs." However, surprisingly, he said that this has not always been easy. "Experiments often fail, and a particularly large obstacle was the adhesive issue with FRPs." He experimented while brainstorming with his students, and after much struggle, he proposed a method that did not rely on adhesives. Failure is said to be the key to success, but perhaps the determination shown by Professor Matsumoto was also a key ingredient.

建物や橋梁の建設・補強にFRPを役立てる

松本 幸大松本幸大教授が研究対象とするのは、ガラス繊維や炭素繊維などを樹脂で固めたFRP(Fiber Reinforced Plastics=繊維強化樹脂)だ。軽量かつ丈夫で形状の自由度が高いFRPは、飛行機や車などに広く用いられているが、松本教授はその材料の特性を生かして、建築物や橋梁などの土木構造物の建設や補強に役立てるための方法論を探究している。FRPを建築・土木材料に使うメリットとは?

軽さと強さを兼ね備えるFRP

20世紀初頭に開発され、戦時中に救命ボートや戦闘機などの材料に用いられて発展、いまや自動車をはじめ、私たちの生活に欠かせない材料となったFRPだが、建築・土木材料として着目されるようになったのは20世紀末になってから。建築・土木資材としてはあまり一般的ではないFRPを研究する理由を、松本教授は次のように語る。

「どんな材料にも利点と欠点はありますが、FPRの最大の利点はなんといってもその軽さと強さにあります。さらに、もとが繊維なので樹脂で固める前は布状で、形状の自由度が非常に高い。鋼のように腐食しないのも大きなメリットです。まだ、建築分野では浸透していませんが、FRPならではの特長を活かす場面がさまざまにあると思っています」

一方、その最大の欠点は、材料を十分理解して、材料自体を設計して使う難しさにある。建設用途では、自動車などのような大量生産に向かないことが多いうえ、肝心の強度を出すには、材料の特性を踏まえたテクニックが必要だと松本教授は指摘する。

「癖のある材料というか、繊維の向きによって強さが変わるんですね。また、強さの観点も二つあって、引っ張ったときにちぎれるかどうかという引張強度は鋼よりも断然強いけれど、力が加わったときにどれくらい変形するかという剛性では、鋼の半分以下になる場合もあります。海外ではFRPだけでつくった建物も存在しますし、日本でも一部にFRPを使った建物はあるものの、現実的には、FRPを単体で使うというより、鋼やコンクリートなどと組み合わせて、適材適所で使っていくのが賢いやり方だと思います」

鉄材の接合部の耐震補強に活かす

他の材料とFRPの組み合わせの例として松本教授が挙げるのが、鋼材やその接合部へのCFRP(炭素繊維強化樹脂)による補強だ。

「工場などで見かけたことがあるかもしれませんが、山形鋼といってL字形の部材を斜めに設置し、ボルトでとめて、構造の一部を担っていることがあります。ところが、古い耐震基準でつくられた建物だと、地震などで力が加わって引っ張られると、ボルトの穴で強度が落ちた部分が発端となって、簡単にちぎれてしまうことがあるんですね。これに対して、溶接による補強やボルトの追加など、さまざまな解決策が開発されていて、実用化もされているのですが、工場によっては火花が出る溶接はできないとか、補強のために何日も工場の稼働を止められないといった理由で、補強工事はあまり進んでいないのが実情です。そこで我々は、ボルトの上から炭素繊維を貼り付けて、樹脂を染み込ませて接着しながら固めるという簡便な方法を開発しました」

大掛かりな準備も不要で、足場を組んだり、重い鉄板などを持ち運んだりする必要はないという。「実験で数カ所に実施した際には、学生が馬脚立に乗って、2時間程度で仕上げることができました」と松本教授。先述した通り、FRPは対象の形にそって巻き付けることができるため、現場で臨機応変に対応できるのが大きな利点だ。

肝心の強度も、飛躍的に高めることができるという。

「実験では、地震の横揺れを想定して水平方向に変形させたところ、120 mmほど動いてもボルトの接合部が切れることはありませんでした。補強がなければ、30 mm程度で切れて、一気に支える力がなくなってしまいます。一方、FRPで補強すれば、120 mmを超えてもしばらくは力を保ち続け、一気に支えを失うことはありません。なお、この粘り強さは炭素繊維の力ではなく、鋼がもともと持っている特性なんですね。つまり、構造物の弱いところをFRPで補うことで、鋼本来の性能を活かすことができるというわけです」

FRPの癖を知り、性能を引き出す

一方、歩道橋などの橋梁では、軽さの利点からすでにガラス繊維を使ったGFRP橋が登場しつつある。しかし、松本教授が「癖のある材料」というように、FRPの使い方には注意が必要だという。

「通常のFRPは繊維がほとんど縦方向(長手方向)に入っているのですが、そのまま繊維に垂直に穴をあけてボルトに引っ掛けると、その部分がトリガーになって、ずるっと抜けてしまうことがあるんですね。つまり、使い方を誤ると、FRPが備えるせっかくの強度が出なくなってしまうのが弱点です。そこで、われわれは繊維の向きを45度傾けて、強度を高める方法を提案しました」

ただし、すべての箇所に特殊なFRPを使おうとすると生産性が落ちてしまったり、材料単価が跳ね上がってしまったりしてしまう。そこで、ボルトのまわりにだけ斜めに繊維が入った材料を貼り付けることで、十分に性能を引き出す方法を編み出した。

「6 mm厚の通常のFRPの両側に0.5 mm厚の繊維が斜めに入るFRPを貼り付けるだけで、耐力は倍以上になります。しかも、想定外の力がかかって壊れたとしても、一気に耐力を失うことはなく、斜めの繊維が引っ掛ってバラバラになったりしない。腐食が心配な海辺の歩道橋や、重機による仮設が困難な場所での橋梁、災害時などに一時的に設置される仮設橋など、軽さと強さを活かして適材適所にFRPを使っていくことができると思います」

接着剤を使わない簡便な方法を開発

もう一つ、FRPの弱点と言えるのが、FRPで補強を行う際に、繊維を接着剤で貼り付けるのだが、接着剤自体が剥がれてしまうと、性能が出なくなってしまうことだ。松本教授は、接着の剥離の兆候を光ファイバセンサでセンシングする方法も手がけるが、そもそも接着剤を使わなければ、剥がれる心配をしなくてもいいことに気づいたという。そこで現在、松本教授は接着剤を使用せずに、材料の性能を最大限に引き出す方法を追究している。

「1970年の大阪万博のお祭り広場に採用された鉄骨立体トラス構造(スペースフレーム)のように、棒状の鉄材を骨組みにした屋根がありますが、設計で想定した以上の力が加わることで、折れてしまうことがあるんですね。その補強として、鉄材の中央部分にCFRPを巻きつけるだけ、というきわめて簡便な方法を開発しました」

作業はじつに簡単で、鋼材の形状に合わせてCFRPをギブスのようにはめるだけ。そのうえで、鋼材の耐力を20〜30%アップさせることに成功したという。CFRPが軽いため、重さの増加は数%程度なので、補強による構造への影響も非常に少ない。

「柱を押しつぶすような力が働いても、CFRPで補強した箇所は変形しないので、補強していない部分が変形するにとどまるんですね。半円のパイプ状のCFRPをかぶせるだけなので、屋根の上などの作業も簡単です。CFRPは材料費の高さがネックですが、軽い部材なのでクレーンを使ったり足場を組んだりする必要もなく、作業に高度なテクニックもいらないため、総合的に見れば、他の補強方法よりも効率的かつ経済的と言えます。しかも、炭素繊維メーカーの御三家と言うように、CFRPは日本のメーカーが大きなシェアを占めていて、我が国の材料技術と融合した建設技術というのもメリットと言えるのではないでしょうか」

地震災害の多い日本において、旧耐震の工場や建物の耐震補強は喫緊の課題だ。松本教授らが開発した、FRPによる簡便な耐震補強の普及に期待したい。

(取材・文=田井中 麻都佳)

取材後記

幼い頃から庭遊びが好きで、手を動かしながら庭木や土を使っていろいろな物をつくっていたと松本教授。将来は構造物をつくる仕事をしたいと、米子高専の建築学科を経て、豊橋技術科学大学へ進学した。

「東海地方は車産業が盛んなせいか、大学ではFRPに触れる機会が多く、気がつけばFRPの専門家になっていました」。もっとも順風満帆ではなかったという、意外な言葉が。「実験で失敗するのはしょっちゅうですし、特に大きな壁にぶち当たったのがFRPの接着問題です」と松本教授。学生と議論しながらさまざまな方法を試し、苦労の末に接着剤に頼らない方法にたどり着いた。失敗は成功のもとと言うけれど、諦めることなく手を動かし続けてきたからこそ、つかむことができた成果にちがいない。

Researcher Profile

Yukihiro Matsumoto

Yukihiro Matsumoto received PhD degree in 2007 from Toyohashi University of Technology, Aichi, Japan. He started his career at National Institute of Technology (KOSEN), Yonago College as an assistant. Since he started his career at Toyohashi University of Technology as an assistant professor in 2009, had been involved in structural engineering including FRP materials for building and civil structures. He is currently a professor at Institute for Research on Next-generation Semiconductor and Sensing Science (IRES2).

Reporter Profile

Madoka Tainaka

Editor and writer. Former committee member on the Ministry of Education, Culture, Sports, Science and Technology Council for Science and Technology, Information Science Technology Committee and editor at NII Today, a publication from the National Institute of Informatics. She interviews researchers at universities and businesses, produces content for executives, and also plans, edits, and writes books.