ここからコンテンツです。

Systems Engineering to Enhance the Performance of Industrial Machines and Robots

Naoki Uchiyama

Professor Naoki Uchiyama's Systems Engineering Laboratory conducts research that can benefit industry, with a focus on sites. Amidst the growing labor shortages that sites are facing, Professor Uchiyama’s Laboratory focuses mainly on working towards optimizing controls and improving efficiency and automation in the mechanical systems of industrial machines and robots . I spoke with Professor Uchiyama about how he connects his work to external organizations, for instance through his Collaborative Research Laboratory that aims to incorporate both research and education.

Interview and report by Madoka Tainaka

Academia that solves problems at sites

The word "system" means all component factors that collectively interact with and affect each other within a mechanism, but the term is used in a variety of situations, so many people might assume that the word is not well defined. Naturally, the scope of system engineering is incredibly vast. Beginning with machines and electricity that form the foundation of mechanical engineering, Professor Uchiyama utilizes a vast range of lateral fields like information, management, and construction to describe system engineering as an academic pursuit that aims to optimize all those fields.

"Essentially, we attempt to understand a real-life phenomenon, create mathematical models, then work to optimize and control that phenomenon. Because we're looking to optimize the issue or problem we've been given, some people may consider the field to be lacking in direction. However, from the perspective of taking the approach that leads from the problem to the solution, I would say that this academic pursuit is very close to how society works."

Collaboration with companies that operate manufacturing sites is indispensable when carrying out research that works backwards from a problem. The laboratory has always carried out joint research with multiple companies, but in 2019, Toyohashi University of Technology offered their first "Collaborative Research Laboratory." It partnered with Kobelco Construction Machinery, a company involved in the development, production, and sales of backhoes and crawler cranes, to develop next-generation cranes.

"Because it was established with funding from an external organization facing the same problems we encounter here at the university, the Collaborative Research Laboratory not only conducts research, but also confers degrees to students. That is to say, it works to develop human resources.

The Collaborative Research Laboratory is funded by external organisations, such as companies, that share a common agenda with the university. In normal joint research, the main focus is on research, and in the case of endowed laboratories, the benefits to the company are not clear, as in principle the intellectual property gained from the research basically belongs to the university. In comparison, the Collaborative Research Laboratory is an excellent initiative that enables both companies and universities to enhance both intellectual property and human capital. In fact, some of our PhD students are currently conducting research under this collaboration.

Transporting suspended loads in the shortest possible time while controlling sway

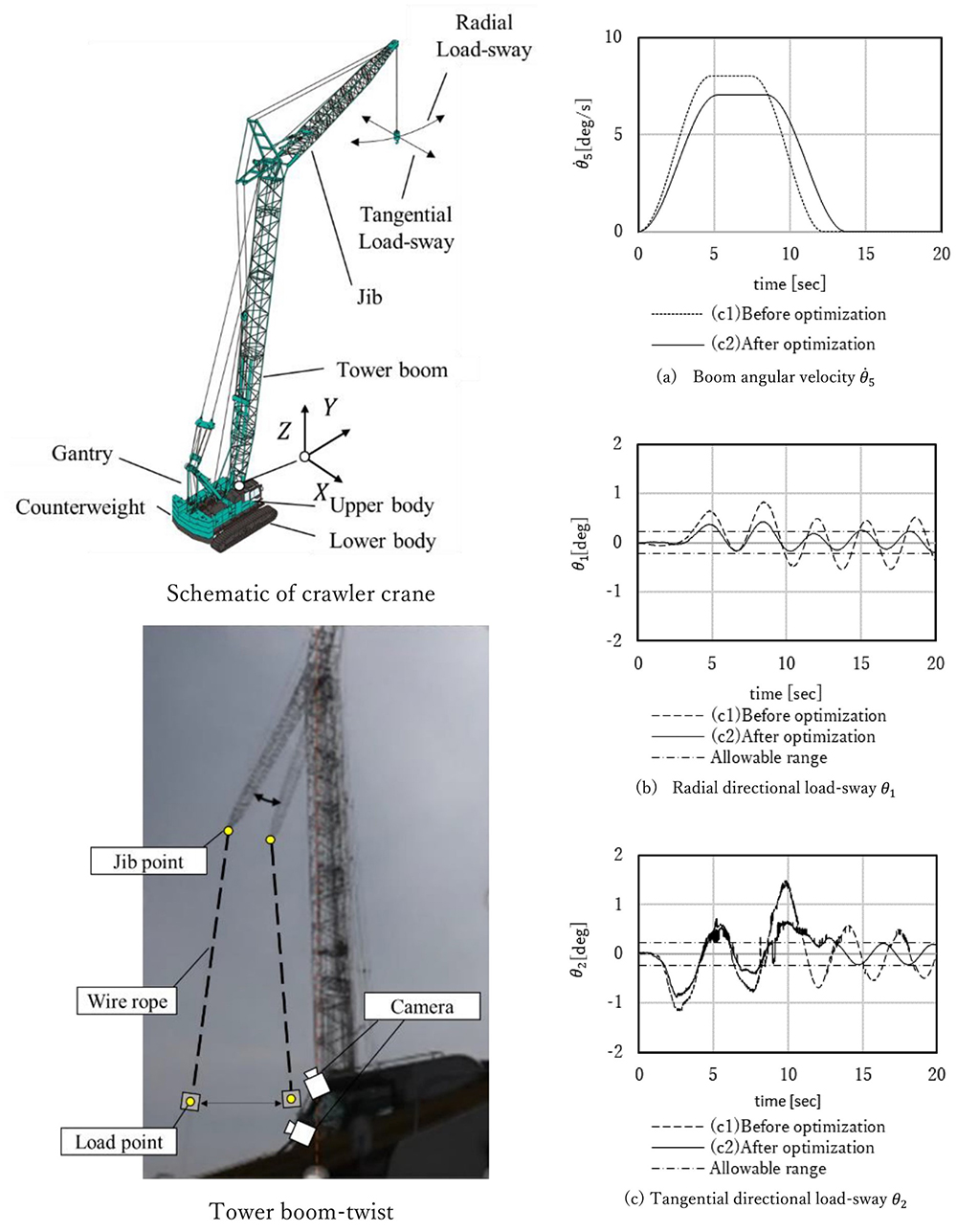

Professor Uchiyama and his group are working on a Collaborative Research Laboratory with Kobelco to control swaying in giant cranes.* When working with giant cranes that have 80 m long cables, even a slight swing of the tip of the crane could result danger from causing the suspended load to sway significantly. That's why they are looking for ways to transport suspended loads in the shortest time possible, and with minimum sway.

Professor Uchiyama said, "Tackling vibration has been a persistent issue for factories and large-scale construction sites. We've created some methods and theories to address that, but these sites still face numerous issues. And with the giant cranes used at outside construction sites, the environment changes each time. Right now, crane operators carefully watch loads and rely on their experience and intuition to operate cranes, but if we can use software to control safety and efficiency, then even inexperienced people could operate cranes and that would help address the labor shortage."

They have already achieved some results. Each part of a giant crane is transported individually and assembled on site, so they are made of lightweight materials to reduce load during transportation. This means, however, that the main frame shakes easily when the crane is moving, which makes it difficult to control sway in the load. To address this, Professor Uchiyama and his team developed a software program that will optimize the crane’s ability to move as swiftly as possible within the limitations set by the need to control speed with regard to vibration periods and to accelerate smoothly to minimize contortions in the crane body.

"Eliminating sway at the destination point is particularly important for safety, but we also had to consider the maximum performance capabilities of the hydraulic motors that move the crane. We input these factors and used our formula to determine the shortest time and smallest amount of sway. We then reproduced the distortion and load sway in a 2 meter crane and verified our results in an experiment. We also tried this in an experimental capacity with a giant crane and obtained a response that we think can be used at construction sites. Our next step is to develop an interface that considers operability on the company side.

Professor Uchiyama’s team are not contenting themselves with only trying to optimize time efficiency however. They are also taking on the challenge of how to move the crane with the least amount of energy while using friction during deceleration and minimising vibration.Doing so would enable them to contribute to increasing energy efficiency.

* The "KOBELCO CONSTRUCTION MACHINERY ADVANCED CRANE LABORATORY" also conducts research in different laboratories within the university for environmental recognition and feedback control using other image processing methods.

Working towards automation to address labor shortages

He is also working on automation. This came about because construction companies are facing such a shortage of labor that they are almost at the point of asking manufacturers to supply experienced operators when purchasing industrial machines.

"Automation will be mandatory in the future, but fully automating something like a giant crane operating outside will be difficult because of the real-time sensing and feedback to account for the effects of wind and other factors. Therefore, I want to only automate simple tasks and rely on humans for complex operations in accordance with vehicle autonomy Level 2, and then gradually build upon that."

In addition to that goal and the Collaborative Research Laboratory, he is also working with the metal recycling business ToyoMetal (Toyohashi) and the construction equipment rental business Rentec Daikei (Toyohashi) to conduct experiments on using large-scale equipment to automatically transfer accumulated metal recycling materials to containers or other locations.

"This uses image processing to detect the edges of the material based on colour change, recognize it as a single item, and then retrieve it with heavy machinery. We've had some successes in site tests and are currently conducting research that could be applied to actual job sites.

Accelerating processes like these could eventually simplify operation to the extent that it could be managed by unskilled operators, or even by older people who might work from home for a few hours at a time."

A double degree program in collaboration with the University of Stuttgart

The actual joint research field work is carried out by master's students, doctoral students, and foreign postdoctoral researchers, and it is essential for these human resources to collaborate with foreign educational institutions as well as the joint research companies.

"The University established a master's double degree program with the University of Stuttgart in Germany. In this program, students study for one year in Toyohashi and one year in Stuttgart and earn credits from both institutions. The students from Stuttgart tend to have a better grounding in basic math and physics, while the students from Toyohashi tend to be adept at conducting experiments and programming. The students inspire each other when they visit each other's countries and collaborate on research."

The programs were carried out remotely while COVID-19 prevented international travel. The postdoctoral researchers who take part in Collaborative Research Laboratory also come from Egypt, Indonesia, and a variety of other countries. Studying in such a cosmopolitan laboratory will be of great use to them after they enter the workforce.

Talking of his future plans, Professor Uchiyama explained that "Our work does not always produce ground-breaking knowledge, but we do make things that help factories right away. Of course, I also hope that we establish theories for control and optimization. I want to keep working toward research that is theoretically guaranteed and beneficial to society."

Reference

Hideki Takahashi, Abdallah Farrage, Kenichi Terauchi, Shintaro Sasai, Hitoshi Sakurai, Masaki Okubo, Naoki Uchiyama, "Sensor-less and time-optimal control for load-sway and boom-twist suppression using boom horizontal motion of large cranes," Automation in Construction,2022, Volume 134.

https://www.sciencedirect.com/science/article/abs/pii/S0926580521005379

M. S. Finkbeiner, N. Uchiyama and O. Sawodny, "Shape Recognition of Material Heaps in Outdoor Environments and Optimal Excavation Planning," 2019 International Electronics Symposium (IES), 2019, pp. 58-62

https://ieeexplore.ieee.org/document/8901670

Reporter's Note

Professor Uchiyama's parents operate a factory that produces automobile parts. Thinking that he might continue the family business, he entered the Shizuoka University Faculty of Engineering through the National Institute of Technology, Numazu College. He eventually discovered an interest in research, earning his PhD at Tokyo Metropolitan University where a teacher of his transferred to, and has been teaching at TUT since 1995. His younger brother currently manages the family business.

The family business faced financial difficulties while he was a student and so he worked a variety of part-time jobs to save money for school and pay for his daily expenses.

"Honestly, back then I sometimes felt that I was wasting my time working at those part-time jobs." Professor Uchiyama says with a wry laugh. However, working at the family business and the part-time jobs taught him about real working conditions on factory floors, and that has helped him with his current research. We hope that he will continue to play an even more active role as a bridge between the university and industry.

「システム工学」で産業機械やロボットの高性能化に貢献

「システム工学研究室」を率いる内山直樹教授は、ものづくりの現場を中心に、産業応用に役立つ研究を手がけている。対象とするのは、主に産業機械やロボットなどで、深刻化する現場の人手不足を背景に、機械システムの最適な制御や効率化、自動化に向けた取り組みを進める。研究と教育の両輪をめざす「共同研究講座」など、外部機関との連携を中心に話を聞いた。

現場の課題解決に役立つ学問

システム(系)とは、相互に影響をおよぼし合う要素で構成される仕組み全体を表す言葉だが、さまざまな場面で使われるため、漠然と感じる人も多いだろう。当然のことながら、システム工学の対象も幅広い。内山教授は、機械工学を基盤とする機械や電気をはじめ、情報、経営、建築土木といった、幅広い分野を横断的に扱い、その最適化をめざす学問だと説明する。

「基本的には、現象を理解して、数理的にモデル化をし、最適化する、あるいは制御する、という取り組みをしています。与えられた対象や課題の最適化が目的なので、根無し草のように思われるかもしれません。もっとも、課題から答えを導くアプローチを取るという意味では、社会に近いところにある学問と言えます」

課題からバックキャストで研究を進めるためには、産業の現場を持つ企業との連携が欠かせない。研究室ではつねに複数の企業との共同研究を進めているが、2019年からは、豊橋技術科学大学初となる「共同研究講座」にも参画。ショベルやクローラクレーンの開発・製造・販売を手がけるコベルコ建機と連携して、次世代クレーンの開発に取り組んでいる。

「共同研究講座というのは、大学と共通の課題を持つ企業などの外部機関からの資金で設置するもので、講座とあるように、研究だけでなく、学位の授与、すなわち人財育成も目的としています。通常の共同研究ではあくまでも研究がメインになりますし、寄付講座の場合は、原則的に研究で得られた知財は大学に帰属するため、企業にとってのメリットが明確ではありません。それらに比べて、共同研究講座は知財と人財の両方を企業と大学双方で充実させることができる、たいへん優れた取り組みです。実際に現在、コベルコ建機から派遣され、博士をめざして研究をしている学生もいます」

吊り荷の揺れを制御しながら、最短時間で運ぶ

内山教授らがコベルコ建機の共同研究講座で担当しているのは、大型クレーンの振動の制御だ※。ロープの長さが80メートルにもなる大型クレーンの場合、先端がわずかに揺れただけで、吊り荷が大きく揺れて危険を伴う。そこで、吊り荷をできるだけ振動させないよう、かつ最短時間で運ぶための方法を探っているのだという。

「産業現場や巨大建造物では、長きにわたり振動が課題となってきました。その解決のための理論も方法もある程度は確立されていますが、現場にはまだ多くの課題が残されています。とくに、建設現場などの屋外で使われる大型クレーンの場合、都度、環境が変わるため、現状は操縦者が吊り荷の揺れ具合を逐一目視しながら、経験と勘を頼りにクレーンを操縦している。これをソフトウエアによって安全に効率よく制御できれば、熟練者でなくてもクレーンを操作できるようになり、人手不足に一役買うことになるでしょう」と内山教授は語る。

すでに成果も出始めている。大型クレーンの場合、各パーツにばらして運び、現地で組み立てるが、運搬時の負荷を軽減するために比較的軽量なのだという。そのため、クレーンを動かす際に本体にねじれが生じやすく、吊り荷の揺れの制御が難しい。そうしたなか、内山教授らは、本体のねじれを最小限に抑えるためになめらかに加速しつつ、振動の周期を考慮して速度をコントロールしながら、最短時間で動かすソフトウェアを開発した。

「とくに安全面で重要なのが、運び先の地点で絶対に振動させないということです。一方、クレーンを動かす際の油圧モーターの性能限界も考慮する必要があります。これらの要素を入れながら、最短時間と揺れの少なさを数式によって導き出しました。さらに高さ2メートル程度のクレーンの模型でねじれや吊り荷の揺れを再現し、実験で検証しました。試験的に大型クレーンでも試し、現場で使えそうだという手応えも得ています。今後は、操作性などに考慮したインターフェイスの開発を企業側で進めていくことになります

さらにここで使った数式を応用して、最短時間を求める代わりに、減速の際の摩擦を最大に生かしつつ、振動を抑えながらクレーンを最小のエネルギーで動かすチャレンジもしている。これにより、エネルギー効率の向上にも貢献できるようになるという。

※「コベルコ建機次世代クレーン共同研究講座」では、そのほか画像処理などを用いた環境認識とフィードバック制御に関して、それぞれ学内の別の研究室で実施している。

人手不足で期待される自動化への取り組み

自動化の取り組みも行っている。その背景には、建設会社がメーカーから産業機械の購入などをする際に、熟練のオペレーターも一緒につけてもらえないかと言うほど、現場で人が足りていないという背景がある。

「今後、自動化は必須ですが、屋外の大型クレーンの場合、風などの影響を受けるため、リアルタイムにセンシングをしてフィードバックをしなければ完全自動化は難しいでしょう。したがって、単純な作業だけ自動化して、複雑な工程は人間が担うような、自動車の自動運転レベル2くらいから始めて、徐々に進展させたいと思っています。」

自動化についてはそのほか、共同研究講座とは別に、金属リサイクル業のトーヨーメタル(豊橋市)、建設機器レンタル業のレンテック大敬(同)と共同で、金属リサイクル原料の堆積を、大型重機を使って自動的にコンテナなどに移し替える実験も行う。

「こちらは画像処理を使い、色の変わり目からエッジ検出をして一塊であると認識して、重機でつかみ取るという方法を採用しています。実験場で成功したので、今後は現場に実装できるよう研究を進めています。

このような取り組みを加速することで、将来的には熟練者でなくても簡単に操作できたり、高齢者が自宅から3時間だけ操作するなんていう働き方も可能になるかもしれません」

ダブルデグリープログラムで独シュツットガルト大学と連携

ところで、共同研究の現場で実働を担うのは、修士や博士課程の学生、海外からのポスドクたちだが、こうした人財についても、共同研究の企業のほか、海外教育機関との連携が不可欠だという。

「とくにドイツのシュツットガルト大学とは、博士前期ダブルデグリープログラムを設置しています。これは、1年は豊橋、もう1年はシュツットガルトで研究することで、それぞれの大学から学位が授与されるというもの。シュツットガルトの学生は数学や物理の基礎に強く、豊橋の学生は実験やプログラミングなどに長けている。学生が行き来しながら共同で研究を行うことで、互いに大いに刺激を受けているようです」

コロナ禍で海外渡航ができない間は、遠隔でプログラムを実施した。共同研究講座に参加しているポスドクもエジプトやインドネシアなど、海外からの人財だ。こうした国際色豊かな研究室での学びは、社会人になってからも大いに役立つだろう。

「うちの取り組みは、学問的には必ずしも先端研究というわけではありませんが、現場ですぐに役立つものばかりです。もちろん、制御や最適化の理論を打ち立てたいという展望もあります。理論的に保証されていて、かつ社会に役立つ研究をめざして、これからも取り組んでいたいですね」と内山教授は展望を語った。

(取材・文=田井中 麻都佳)

取材後記

内山教授のご実家は、自動車部品の加工工場を経営している。いずれ家業を継ぐかもしれないと、沼津工業高等専門学校を経て静岡大学工学部へ。結局、研究の方が面白くなってしまい、恩師が移籍した先の東京都立大学で博士を取得し、1995年から豊橋で教鞭を執るようになった。なお、家業は弟さんが継ぐことになったそうだ。

学生時代、家業の経営が一時的に苦しくなった折には、学費や生活費を稼ぐために、さまざまなアルバイトをしたこともあるという。

「正直、バイトで時間を無駄にしたと思うこともあります」と苦笑いする内山教授だが、家業にしろアルバイトにしろ、現場の苦労を知る環境に身を置いたことが、いまの研究に生かされているように思う。今後も大学と企業の架け橋として、一層の活躍を期待しています。

Researcher Profile

Naoki Uchiyama

Naoki Uchiyama received PhD degree from Tokyo Metropolitan University in 1995. He started his career as a research associate at Toyohashi University of Technology, had been involved in systems engineering, control engineering, and mechatronics. He has been worked as a professor since 2015.

Reporter Profile

Madoka Tainaka

Editor and writer. Former committee member on the Ministry of Education, Culture, Sports, Science and Technology Council for Science and Technology, Information Science Technology Committee and editor at NII Today, a publication from the National Institute of Informatics. She interviews researchers at universities and businesses, produces content for executives, and also plans, edits, and writes books.

ここでコンテンツ終わりです。