ここからコンテンツです。

Smooth Jerk-limited Trajectory Generation and Nonlinear Friction Compensation for Feed Drive Systems

The International Federation of Automatic Control (IFAC) 2017, Application Paper Prize

By SIMBA KENNETH RENNY

The systems engineering laboratory in the department of mechanical engineering at Toyohashi University of Technology in collaboration with the institute for system dynamics at the University of Stuttgart, has developed methods for generating smooth motion trajectories for feed drive systems for efficient manufacturing and energy saving. The method is based on quintic Bézier curves and the altered bang-bang approach to ensure smooth velocity transitions within the motion trajectory. In addition, a contouring controller with a feedforward friction compensator was applied in order to smoothly track the designed trajectory by canceling out the effect of friction forces.

The result of this study was presented during the 20th World Congress, The International Federation of Automatic Control (IFAC), Toulouse, France, July, 2017 and published by ELSEVIER. Consequently, the researchers of this study were awarded with the IFAC Application Paper Prize (Finalist). The prize is given for outstanding technical contributions at an IFAC Congress in the area of control applications. The IFAC congress is held once in every three years and during the 20th IFAC congress, 2,800 out of 4,267 submissions were accepted for presentation. From the 2,800 accepted submissions, five papers including our paper were selected and awarded as the application paper prize finalists.

Details of the research

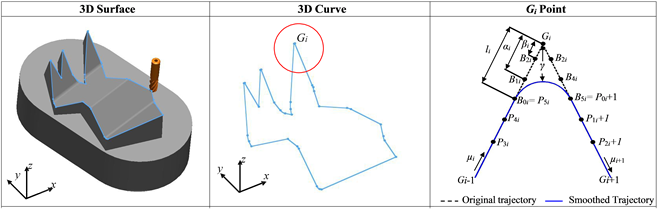

Computer numerical control (CNC) machines are widely used to manufacture complex components that are required to be very precise to comply with the rising demand. In order to achieve the desired manufacturing quality, motion trajectories must be traversable without violating systems’ constraints such as a permissible acceleration and jerk. Generally, the trajectories have to be at least second order differentiable in order to achieve a continuous velocity and acceleration. Linearly interpolated trajectories have been used for decades due to their simplicity in design and implementation. However, these linear trajectories cause undesired performance, such as stops between trajectories’ segments, unnecessary time and energy consumptions and wear on the system parts.

For improvement of motion trajectories, many methods have been proposed in the literature and most of them focus on smoothing the linear interpolated tool-path points using curve fitting techniques. For densely tool-path points, curve fitting techniques exhibit oscillations in the trajectory because high-order spline curves are numerically unstable. On the other hand, cubic parametric spline curves are used to smoothly interpolate the linear tool-path points. They are infinitely differentiable when used as a single curve, however, their differentiability is limited to first-order when two or more curves are connected.

In this study, a method for generating smooth motion trajectories using quintic Bézier curves and smooth velocity profiles based on the altered bang-bang approach was proposed. The altered bang-bang approach allows for smooth velocity transitions between the spline curves, such that low-velocity values can be used during the motion start and end, and in all areas with high curvatures. Since it is well known that mechanical systems cannot instantly accelerate to high velocities and that the velocity is inversely proportional to the curvature, smooth reference velocity ensures that the motion acceleration and jerk are within the permissible range.

In addition to the velocity profile matter, mechanical systems experience friction forces which vary nonlinearly with velocities. Therefore, on implementing a smooth velocity profile, a contouring controller with a feed forward friction compensator was applied in order to smoothly track the designed trajectory by canceling out the effect of friction forces. Experimental verification was conducted and results showed that the proposed method is effective for improving the performance of CNC systems.

Behind-the-scenes story

We had previously successfully developed a method to automatically generate smooth trajectories for mobile robots based on the assigned via-points. In addition, other members of our laboratory studied and developed a nonlinear motion controller with "a" friction compensator for feed drive systems. The performance of the designed controller was found dependent on the nature of the applied trajectory. Tracking performance was much better if the trajectory is smooth enough to be traversed by the system. On the other hand, poor performance was observed when traversing trajectories with high curvatures. It was in this light that we studied the method previously used for mobile robots and modified it for application to feed drive systems.

Future Research

The research team of this study believe that the proposed method will be adopted for industrial applications to enhance manufacturing performance. In addition, this study can be applied to other motion systems, such as autonomous mobile robots and driverless cars.

This study is partly sponsored by the Japan Society for the Promotion of Science (JSPS).

Reference

Kenneth Renny Simba, Gunter Heppeler, Ba Dinh Bui, Yogi Muldani Hendrawan, Oliver Sawodny, Naoki Uchiyama, Bézier Curve Based Trajectory Generation and Nonlinear Friction Compensation for Feed Drive Contouring Control, IFAC-PapersOnLine, Volume 50, Issue 1, (2017), Pages 1944-1951.

https://doi.org/10.1016/j.ifacol.2017.08.388.

産業機械駆動系の加々速度制限を考慮した滑らかな動作軌道生成と非線形摩擦補償

International Federation of Automatic Control (IFAC) 2017, Application Paper Prize

By シンバ ケニス レニー

豊橋技術科学大学機械工学系システム工学研究室とドイツのシュトゥットガルト大学システムダイナミクス研究所は、効率的な生産と省エネルギー化のための産業機械駆動系の滑らかな動作軌道生成法を提案しました。提案法は5次のベジエ曲線とバンバン型の加々速度に基づき滑らかな速度遷移を保証します。さらに、その軌道への動作追従のためにフィードフォワード型の摩擦補償を適用しました。

本成果は、20th World Congress, The International Federation of Automatic Control (IFAC), Toulouse, France, July, 2017に報告し、Elsevier社の論文に採択されました。さらに、制御応用分野の論文を対象としたIFAC Application Paper Prize (Finalist)として表彰されました。The IFAC World congressは3年に一度開催される制御分野の世界的な会議であり、20回目を迎える今回は4,267の投稿論文のうち2,800件が採択され、本論文を含む全部で5編の論文が同賞を受賞しました。

研究内容の詳細

日本の代表的な産業分野の一つであるCNC工作機械などの産業機械装置は世界中の工場で広く利用され、製造する製品の高度化に伴い、一層の高速高精度が期待されています。このために、加速度や加々速度の制限を満たしつつ、駆動系が追従可能となるよう産業機械の動作軌道を生成することが必要です。動作軌道は駆動系の速度および加速度が滑らかになるよう、少なくとも2階時間微分可能となることが望まれます。しかしながら、軌道設計や実装の容易性の点から線形補間軌道も多く用いられており、急な加減速等による動作効率の低下、消費エネルギーの増大、機械磨耗等の点から改良が必要とされます。

動作軌道の改良法についての研究が進められ、多くの場合にはカーブフィッティングの応用が検討されています。しかしながら、例えば高次のスプライン曲線は数値的に不安定であり、振動的な軌道の発生が指摘されています。また、3次のスプライン曲線では滑らかな補間が可能ですが、軌道を接続するときに微分可能性が制限されます。

そこで私たちの研究チームでは、5次のベジエ曲線とバンバン型の加々速度に基づく手法を提案しました。これは、速度軌道の滑らかな接続を可能にします。また、機械装置では瞬時の大きな加減速や、曲率の高い箇所での高速動作は望ましくないため、本提案では加速度および加々速度制限を満たしつつ、動作始点/終点あるいは曲率の高い箇所での速度抑制が可能な構成となっています。

摩擦力は一般に動作速度に関して非線形性を有しますが、産業機械の高精度動作に対して支配的な外乱となるため、滑らかな速度軌道の実装に伴い、フィードフォワード型の摩擦補償をさらに応用しました。これにより、非線形摩擦力の影響を制御的にキャンセルでき、より高精度な軌道追従が可能になります。実験により産業機械の動作性能の改善が確認されました。

開発秘話

本研究に先立ち、私たちは与えられた経由点を滑らかに移動する車輪ロボットの動作軌道生成法を提案していました。また、研究室のメンバーが産業機械駆動系のための摩擦補償を有する非線形制御法について研究していました。これらの研究を通じて、制御性能が目標動作軌道の性質に大きく依存することを確認していました。すなわち、目標動作軌道が十分滑らかであれば、より優れた制御性能が得られます。一方、高い曲率を有する目標動作軌道では、制御性能が低下します。この点から、先に提案した車輪ロボットのための動作軌道生成法を産業機械駆動系へ応用するアイデアを思いつき検討を行いました。

今後の展望

私たち研究チームは、今回の提案法が産業機械の生産性能向上のほか、自律移動ロボットなど多くの機械駆動装置への適用を期待しています。

Student Profile

| Name | SIMBA KENNETH RENNY |

|---|---|

| Affiliation | Department of Mechanical Engineering Current: Musashi Seimitsu Industry Co., Ltd. |

| Title | Doctor course student (when he got the prize) |

| Fields of Research | precision control, motion planning, feed drives |

ここでコンテンツ終わりです。