Inada, Ryoji

| Affiliation | Department of Electrical and Electronic Information Engineering |

|---|---|

| Concurrent post | Institute for Research on Next-generation Semiconductor and Sensing Science (IRES²) |

| Title | Professor |

| Fields of Research | Energy-Related Chemistry / Electirical and Electronic Material Engineering / Electrochemistry |

| Degree | Doctor of Engineering (Toyohashi University of Technology) |

| Academic Societies | The Institute of Electric Engineers of Japan / The Electrochemical Society of Japan / The Ceramic Society of Japan / The Solid State Ionics Society of Japan / Material Research Society (USA) / The Electrochemical Society (USA) |

| inada.ryoji.qr@ Please append "tut.jp" to the end of the address above. |

|

| Laboratory website URL | https://www.cec.ee.tut.ac.jp/ |

| Researcher information URL(researchmap) | Researcher information |

Research

Main research subjects of our laboratory include:

(1) Research and development for oxide-based all-solid-state batteries.

(2) Research of new anode materials for highly safe lithium-ion batteries

(3) Research and Application of Ion-Conductive Ceramics

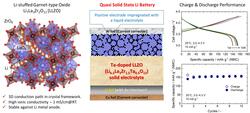

Theme1:Research and development for oxide-based all-solid-state batteries

Overview

Structure and charge and discharge properties of quasi solid-state Li battery with oxide solid electrolyte separator.

Structure and charge and discharge properties of quasi solid-state Li battery with oxide solid electrolyte separator.All-solid-state lithium-ion batteries (LIBs), using nonflammable inorganic solid Li-ion conductor as an electrolyte, is expected as one of the next generation energy storage devices, because its safety and reliability are much superior to present LIB with flammable organic carbonate liquid electrolyte. To realize high performance all solid state LIBs, our group are developing oxide solid electrolytes with high ionic conductivity and chemical stability against electrode materials and the processing for solid-solid interface between electrode and solid electrolyte in solid state batteries. In addition, we are also working to improve the performance of materials for all-solid-state sodium-ion batteries, which are expected to reduce costs.

Selected publications and works

(1) A. Itaya, Y. Ono, K. Yamamoto, R. Inada, Characterization of Na2Zn2TeO6 ceramic solid electrolyte densified by hot pressing, International Journal of Applied Ceramic Technology 21, 2024, 311-318.

DOI: 10.1111/ijac.14508

(2) K. Akimoto, Y. Sugimura, R. Inada, Characterization of garnet-type Li6SrLa2Bi2O12 ceramic electrolyte for all-solid-state Li-ion batteries, Materials Letters 349, 2023, 134866.

DOI: 10.1016/j.matlet.2023.134866

(3) Y. Yamazaki, S. Miyake, K. Akimoto, R. Inada, Effect of Ga2O3 addition on the properties of garnet-type Ta-doped Li7La3Zr2O12 solid electrolyte, Batteries 8(10), 2022, 158.

DOI: 10.3390/batteries8100158

(4) S. Teshima, Y. Ono, N. Goto, R. Inada, Electrical conducting properties of Na2Zn2TeO6 thick films fabricated by aerosol deposition, Materials Letters 324, 2022, 132640.

DOI: 10.1016/j.matlet.2022.132640

(5) A. Itaya, K. Yamamoto, R. Inada, Sintering temperature dependency on sodium‐ion conductivity for Na2Zn2TeO6 solid electrolyte, International Journal of Applied Ceramic Technology 18, 2021, 2085-2090.

DOI: 10.1111/ijac.13847

(6) A. Itaya, K. Yamamoto, R. Inada, Y. Sakurai, Effect of excess Na contents in precursor on the property of Na2Zn2TeO6 ceramic solid electrolyte, Materials Letters 284, 2021, 128941.

DOI: 10.1016/j.matlet.2020.128941

(7) R. Inada, A. Takeda, Y. Yamazaki, S. Miyake, Y. Sakurai, V. Thangadurai, Effect of postannealing on the properties of a Ta-doped Li7La3Zr2O12 solid electrolyte degraded by Li dendrite penetration, ACS Applied Energy Materials 3, 2020, 12517-12524.

DOI: 10.1021/acsaem.0c02474

(8) H. Hosokawa, A. Takeda, R. Inada, Y. Sakurai, Tolerance for Li dendrite penetration in Ta-doped Li7La3Zr2O12 solid electrolytes sintered with Li2.3C0.7B0.3O3 additive, Materials Letters 279, 2020, 128481.

DOI: 10.1016/j.matlet.2020.128481

(9) R. Inada, K. Okuno, S. Kito, T. Tojo, Y. Sakurai, Properties of lithium trivanadate film electrodes formed on garnet-type oxide solid electrolyte by aerosol deposition, Materials 11(9), 2018, 1570.

DOI: 103390/ma11091570

(10) R. Inada, S. Yasuda, H. Hosokawa, M. Saito, T. Tojo, Y. Sakurai, Formation and stability of interface between garnet-type Ta-doped Li7La3Zr2O12 solid electrolyte and lithium metal electrode, Batteries 4(2), 2018, 26.

DOI: 10.3390/batteries4020026

(11) R. Inada, T. Okada, A. Bando, T. Tojo, Y. Sakurai, Properties of garnet-type Li6La3ZrTaO12 solid electrolyte films fabricated by aerosol deposition method, Progress in Natural Science: Materials International 27, 2017, 350-355.

DOI: 10.1016/j.pnsc.2017.06.002

(12) R. Inada, S. Yasuda, M. Tojo, K. Tsuritani, T. Tojo, Y. Sakurai, Development of lithium stuffed garnet-type oxide solid electrolytes with high ionic conductivity for application to all-solid-state batteries, Frontiers in Energy Research 4, 2016, 26.

DOI: 10.3389/fenrg.2016.00028

(13) K. Kimura, K. Wagatsuma, T. Tojo, R. Inada, Y. Sakurai, Effect of composition on lithium-ion conductivity for perovskite-type lithium-strontium-tantalum-zirconium-oxide solid electrolytes, Ceramics International 42, 2016, 5546-5552.

DOI: 10.1016/j.ceramint.2015.12.133

(14) R. Inada, K. Ishida, M. Tojo, T. Okada, T. Tojo, Y. Sakurai, Properties of aerosol deposited NASICON-type Li1.5Al0.5Ge1.5(PO4)3 solid electrolyte thin films, Ceramics International 41, 2015, 11136-11142.

DOI: 10.1016/j.ceramint.2015.05.062

Keywords

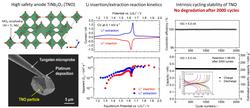

Theme2:Research for advanced high-safety lithium-ion batteries

Overview

Graphite is used as the dominant anode material for commercial lithium-ion batteries (LIBs). However, it intercalates Li-ion at a low potencial close to that of Li-plating, which results in a safety risk due to high surface Li-plating (Li dendrite, a potential cause of short circuits inside a battery). Lithium titanate Li4Ti5O12 (LTO) with cubic spinel structure is considered as an alternative anode material with high safety and excellent cycling stability, but its theoretical capacity is limited to 175 mAh/g, which is much smaller than graphite. Small capacity and high operation potential (1.5V vs. Li/Li+) of LTO sacrifices cell voltage and cell energy density seriously. To realize highly safe LIBs with high cell energy density, we are studying new anode materials with large capacity, good cycling stability and appropriate operating potential higher than that for Li-plating.

Selected publications and works

(1) D. Azuma, R. Inada, Characterization of Sn4P3 film formed by aerosol deposition for lithium-ion battery anode with liquid electrolyte and solid polymer electrolyte, Thin Solid Films 761, 2022, 139537.

DOI: 10.1016/j.tsf.2022.139537

(2) T. Moritaka, Y. Yamashita, T. Tojo, R. Inada, Y. Sakurai, Characterization of Sn4P3–carbon composite films for lithium-ion battery anode fabricated by aerosol deposition, Nanomaterials 9(7), 2019, 1032.

DOI: 10.3390/nano9071032

(3) T. Tojo, S. Kawashiri, T. Tsuda, M. Kadowaki, R. Inada, Y. Sakurai, Electrochemical performance of single Li4Ti5O12 particle for lithium-ion battery anode, Journal of Electroanalytical Chemistry 836, 2019, 24-29.

DOI: 10.1016/j.jelechem.2019.01.061

(4) R. Inada, R. Kumasaka, S. Inabe, T. Tojo, Y. Sakurai, Li+ insertion/extraction properties for TiNb2O7 single particle characterized by a particle-current collector integrated microelectrode, Journal of The Electrochemical Society 166, 2019, A5157-A5162.

DOI: 10.1149/2.0241903jes

(5) R. Inada, T. Mori, R. Kumasaka, R. Ito, T. Tojo, Y. Sakurai, Characterization of vacuum-annealed TiNb2O7 as high potential anode material for lithium-ion battery, International Journal of Applied Ceramic Technology 16, 2019, 264-272.

DOI: 10.1111/ijac.13058

(6) K. Narumi, T. Mori, R. Kumasaka, T. Tojo, R. Inada, Y. Sakurai, Syntheis and properties of Li3VO4-carbon composite as negative electrode for lithium-ion battery, AIP Conference Proceedings 1865, 2017, 060004.

DOI: 10.1063/1.4993380

(7) T. Takashima, T. Tojo, R. Inada, Y. Sakurai, Characterization of mixed titanium-niobium oxide Ti2Nb10O29 annealed in vacuum as anode material for lithium-ion battery, Journal of Power Sources 276, 2015, 113-119.

DOI: 10.1016/j.jpowsour.2014.11.109

(8) R. Inada, K. Shibukawa, C. Masada, Y. Nakanishi, Y. Sakurai, Characterization of as-deposited Li4Ti5O12 thin film electrode prepared by aerosol deposition method, Journal of Power Sources 253, 2014, 181-186.

DOI: 10.1016/j.jpowsour.2013.12.084

Keywords

Theme3:Research and application of ion-conductive ceramics

Overview

Ion-conductive ceramics (solid electrolytes) are expected to be applied to detection devices for oxygen-containing gases such as CO2, NOx, and SOx, which cause global warming and environmental pollution, and separation membranes for recovering specific elements dissolved in liquids. We are developing on oxide-based ceramic solid electrolyte materials with the properties required for each application.

Selected publications and works

(1) K. Kimura, K. Wagatsuma, T. Tojo, R. Inada, Y. Sakurai, Effect of composition on lithium-ion conductivity for perovskite-type lithium-strontium-tantalum-zirconium-oxide solid electrolytes, Ceramics International 42, 2016, 5546-5552.

DOI: 10.1016/j.ceramint.2015.12.133

(2) R. Inada, K. Kusakabe, T. Tanaka, S. Kudo, Y. Sakurai, Synthesis and properties of Al-free Li7-xLa3Zr2-xTaxO12 garnet related oxides, Solid State ionics 262, 2014, 568-572.

DOI: 10.1016/j.ssi.2014.04.005

(3) R. Inada, K. Kimura, K. Kusakabe, T. Tojo, Y. Sakurai, Synthesis and lithium-ion conductivity for perovskite-type Li3/8Sr7/16Ta3/4Zr1/4O3 solid electrolyte by powder-bed sintering, Solid State Ionics 261, 2014, 95-99.

DOI: 10.1016/j.ssi.2013.09.008

Keywords

Title of class

Electric Machinery 2 (B12530070) / Electrical Power Engineering 2 (B12620050) / Measurement and Instrumentation (B12620390) / Electrical Energy Conversion (M22622020) / Advanced Electrical Systems 2 (D32030040) / Advanced Electrical Systems 2(D52030040)/ Electrical Technology and Materials 2(M42630190)

Others (Awards, Committees, Board members)

Other Research Theme

◆Research for multivalent ion batteries

Awards

2010: Excellent Paper Award for Young Scientists, The 11th IUMRS International Conference in Asia (IUMRS-ICA 2010)