Pick UP

Press release

We are TUT

Research

3 Million Cells per Minute: Parallel Microdevice with AI-Powered Single-Cell Analysis

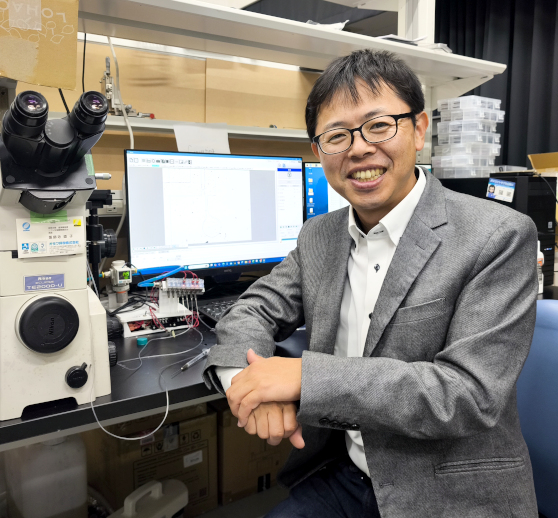

Nagai Moeto

Professor, Institute for Research on Next-generation Semiconductor and Sensing Science

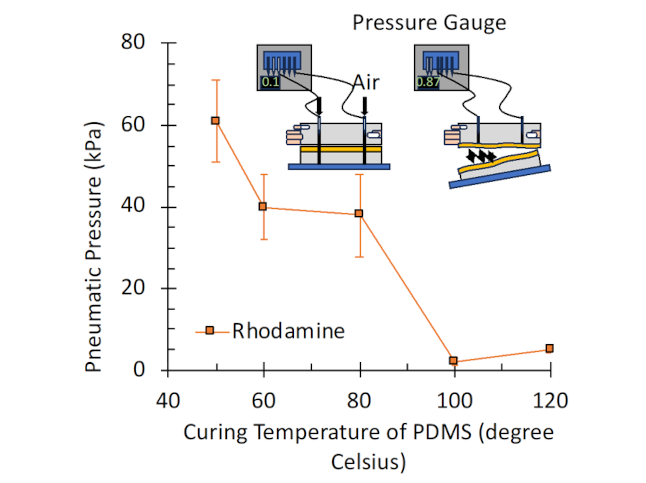

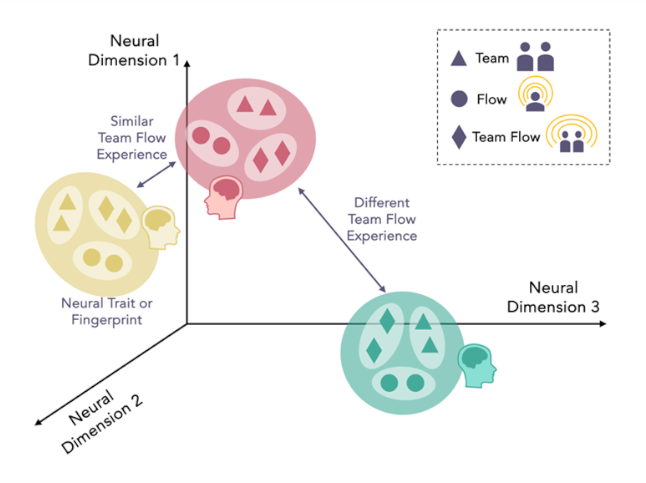

Researchers at the Indian Institute of Technology (IIT) Madras and Toyohashi University of Technology (TUT) have developed an integrated platform that advances both fronts simultaneously. The platform combines two modules: a massively parallel through‑hole cell‑squeezing mechanoporation device for high‑throughput intracellular delivery, and an automated single‑cell image‑cytometry pipeline built on Mask R‑CNN.