Takayama, Kotaro

| Affiliation | Department of Mechanical Engineering |

|---|---|

| Concurrent post | Research Center for Agrotechnology and Biotechnology Department of Architecture and Civil Engineering Institute for Research on Next-generation Semiconductor and Sensing Science (IRES²) |

| Title | Professor |

| takayama@ Please append "tut.jp" to the end of the address above. |

|

| Researcher information URL(researchmap) | Researcher information |

Research

The main research and development of this laboratory are relating to environmental control and optimum design of intelligent greenhouse and plant factory, plant diagnosis/monitoring for agricultural production.

Theme1:Optimum design of intelligent greenhouse and plant factory for sustainable food production

Overview

The intelligent greenhouse is an advanced greenhouse equipped with an automated environmental control system and conducting year-round plant production of various plants including vegetables and ornamental foliage plants under the sun. And, the plant factory is a facility achieving an extremely steady plant production under fully controlled environmental condition without sunlight. Currently, the computerized plant production based on the concept of Speaking Plant Approach (SPA) attracts attentions as an implementable key technology to achieve a significant productivity improvement in intelligent greenhouse and plant factory. The concept of SPA defines that the optimization of cultivation conditions should be based on measurements of the plant biological and physiological information and it is getting feasible according to a recent development of information technology, i.e. artificial intelligence and bioinformatics symbolized by omics.

Theme2:Plant diagnosis robot and precise plant data for agricultural production

Overview

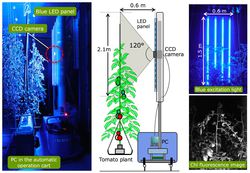

Chlorophyll fluorescence (CF) imaging technique is useful to evaluate the photosynthetic functions. CF is red light emission from plant leaves, which is generated by residual light energy that is not used for photosynthetic reactions. So, the precise measurement of CF allows us to evaluate the status of photosynthetic functions without touching the plants. The figure shows a CF imaging robot, which was developed in our previous studies and come onto the market in 2015. The CF imaging robot proved an apparent heterogeneous distribution of photosynthetic functions across the cultivation area (> 1 ha). Such information is probably useful to optimize the environmental control and crop maintenance strategies.

Theme3:Real-time monitoring of photosynthesis and transpiration

Overview

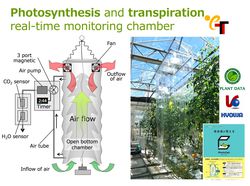

A variety of instrumentations for environmental control such as CO2 enrichment, supplemental lighting and air circulation have been installed in commercial greenhouses and utilized to increase the net photosynthesis. However, the extent of the contribution of each environmental control instrumentation to the crop photosynthesis is not clear. We developed a real-time photosynthesis and transpiration monitoring system that is able to be installed in commercial greenhouses and applied to obtain the time course of photosynthesis and transpiration of full-size tomato plant grown in a semi-commercial greenhouse. This system is going to be commercially available until 2020.