Research highlights

Industrial electronics: reducing the energy consumption of feed-drive systems

Servo systems are used in a wide variety of industrial applications for providing accurate, high-speed motion of mechanical components. Notably, the extensive use of servo systems necessities careful management and reduction of their electrical power consumption. Therefore, as Abd El Khalick Mohammad and colleagues at the Toyohashi University of Technology explain in their report, “the reduction of the consumed energy by feed-drive systems has become an important issue in modern machining technology”.

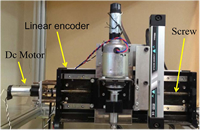

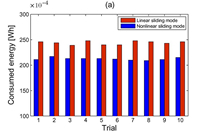

The Toyohashi Tech team led by Naoki Uchiyama describe a new technique for enhancing the performance of ball-screw-driven mechanisms actuated by servo drives. The sliding-mode control is a known and effective method to drive systems subject to external disturbances, but reaching the target via a linear sliding surface strategy leads to overshooting—a significant waste of energy. The researchers demonstrated how a suitably designed non-linear sliding surface enables the variation of the system’s damping ratio to achieve fast response with small overshoot, thereby providing a smaller tracking error than conventional methods.

This innovative control routine was tested experimentally in a ball-screw feed-drive system driven by a dc servo motor. Comparison with standard linear methods demonstrated a 35% reduction in tracking error magnitude. Such enhanced accuracy paves the way for systematic energy savings, where by operating the system with a smaller control input voltage comparable performances were obtained with almost a 13% reduction in energy consumption.

- Reference:

- A.E.K. Mohammad, N Uchiyama and S Sano.

- Reduction of Electrical Energy Consumed by Feed-Drive Systems Using Sliding-Mode Control With a Nonlinear Sliding Surface.

- IEEE Transactions on Industrial Electronics 61(6), 2875 (2014)

- doi:10.1109/TIE.2013.2275975

Naoki Uchiyama

Fig.1: A novel non-linear sliding surface controller for ball-screw feed-drive systems was developed by researchers from the Toyohashi University of Technology. Servo-drive systems are widely used in industry, in particular for power efficiency applications.

Enlarge Image

Fig. 2: Non-linear sliding surface (blue) yields an energy reduction of approximately 13% compared to standard linear methods.

Enlarge Image