ここからコンテンツです。

A case of internal observation using X-ray CT, aiming to discover the vibration damping mechanism

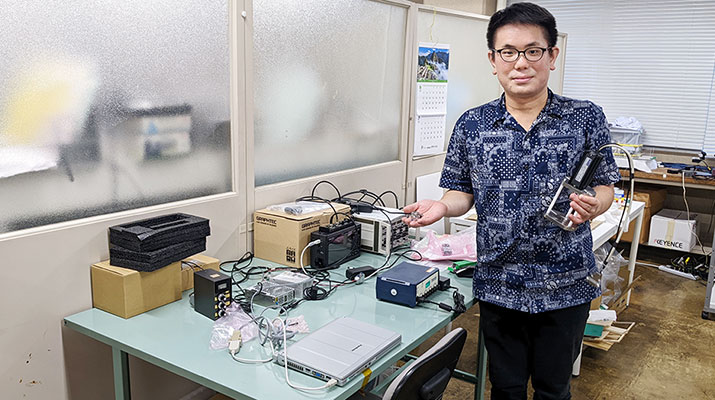

Towards the development of next-generation functional rubber materials Masami Matsubara

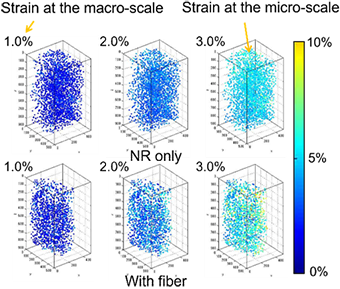

A research team led by Professor Nobuyoshi Tsujiuchi and Professor Akihito Ito of the Faculty of Science and Technology, Doshisha University, and Dr. Asahiro Hase (currently at the National Institute of Advanced Industrial Science and Technology) of the Department of Mechanical Engineering, Toyohashi University of Technology and Hyogo Prefectural Industrial Technology Center, has used synchrotron radiation X-ray CT to reveal that the improved vibration damping of rubber materials due to the composite of fine particles is related to the deformation behavior of microstructure. They discovered that performing deformation evaluations at the macroscale (in the order of mm) and at the microscale (space resolution when using the X-ray CT: 500nm) at the same time can obtain the internal nonuniform deformation of a material in the scale of tens of mm. The results of the research were released online on May 9, 2022 in Polymer Testing.

https://www.sciencedirect.com/science/article/pii/S0142941822001490

For machine structures, it is vitally necessary that vibrations and noises be appropriately controlled to ensure performance and safe operation. There are many cases where design limits and operating limits are determined by damping properties, which control the amount of vibration. Generally, energy loss caused by the deformation of rubber (a determination factor in vibration damping) is described as a loss caused by the change of the arrangement of the filler particles blended into the polymer (pain effect). As an experimental rule of macro mechanical properties, it is believed that its main control factors are the diffusion, interface and orientation of the filler. However, technologies predicting damping properties based on these main control factors have not yet been established. One of the reasons for this is the difficulty of observing three-dimensional structures.

Transmission electron microtomography (TEMT) and X-ray Computed Tomography are methods of observing the three-dimensional structure of a high polymer material. TEMT requires the thickness of a specimen to be several hundreds of nm, and one problem with it is that it tends to generate artifacts (false images). It is difficult to obtain image contrast in X-ray CT, and there are fewer cases of application for polymer materials when compared to TEMT. Furthermore, when examining rubber materials, another problem of X-ray CT is that the sample's physical properties change due to a curing reaction caused by exposure to X-ray radiation. Because the sensitivity of image sensors and high-speed radiographic technologies have improved gradually in recent years, it is now possible to obtain CT images with contrast with only short-term X-ray radiation exposure.

Therefore, the research team used a synchrotron radiation facility to perform micro X-ray CT of fine particle-filled rubber materials in a tiny deformation field. They developed a compact tensile tester that can be mounted on X-ray CT machines and also evaluated deformation behavior at the macroscale using the tensile test. Based on the evaluation result at the macroscale, they discovered that in the deformation area that can be judged as an elastic deformation area, deformation at the microscale became nonuniform according to the amount of change.

In the vibration field, the damping property is a parameter that is observed under dynamic conditions. On the other hand, from the viewpoint of material development, the damping property should be determined at the time when the structure is determined. Therefore, we attempted measurement using micro X-ray CT with the expectation that some difference would appear even in static deformation.

Currently, the research team is attempting to perform dynamic X-ray CT. They expect this to clarify the deformation behavior of the internal structure at the mesoscale and the relationship between the control factors associated with a filler and its damping properties.

This research was conducted with Grants-in-Aid for Scientific Research from the Japan Society for the Promotion of Science (JP16K18041, JP18K13715) and supported by the Support Program for Formation of Strategic Research Infrastructure for Private Universities (2013 to 2017, Doshisha University). We express our gratitude to them.

Reference

M.Matsubara, S.Teramoto, T.Komatsu, S.Furuta, M. Kobayashi, S. Kawamura, A. Nagatani, N.Tsujiuchi, A.Ito (2022). Three-dimensional strain evaluation of short-fiber-reinforced natural rubber using micro X-ray computed tomography.

Polymer Testing, https://www.sciencedirect.com/science/article/pii/S0142941822001490.

振動減衰メカニズム解明へ向けたX線CTによる内部観察事例

次世代機能性ゴム材料の開発に向けて松原 真己

豊橋技術科学大学機械工学系と兵庫県立工業技術センター 長谷 朝博博士(現・産業技術総合研究所)、同志社大学理工学部 辻内 伸好教授、伊藤 彰人教授の研究チームは、シンクロトロン放射光によるX線CTを用いて微粒子の複合化に伴うゴム材料の振動減衰の向上が微細構造の変形挙動に関係することを明らかにしました。マクロな変形評価(mmオーダー)とミクロな評価(X線CTによる空間分解能500nm)を同時に行うことで、材料内部の変形の不均一性が数十mmのスケールで確認できることを突き止めました。本研究成果は、Polymer Testing誌に2022年5月9日付けでオンライン公開されました。

https://www.sciencedirect.com/science/article/pii/S0142941822001490

機械構造物では振動や騒音を適切に抑えることは性能確保や安全な稼働を行う上で必要不可欠であり、設計限界や運用限界は振動の大きさを抑える減衰特性によって決まる事例が多くあります。一般にゴムの変形によるエネルギー損失(振動減衰の決定因子)は、ポリマーに配合された充てん剤粒子の配列変化により生じる損失(ペイン効果)として説明され、巨視的力学物性の経験則から充てん剤の分散、界面、配向が主要制御因子と考えられています。しかしながら、それら主要制御因子から減衰特性を予測する技術の確立までには至っていません。その原因の一つに三次元構造の観察が難しいという点が挙げられます。

高分子を中心とした材料の三次元構造の観察法としては透過型電子顕微鏡によるコンピュータトモグラフィー(Transmission electron microtomography,以下TEMT)、X線CT(X-ray Computed Tomography)が挙げられます。TEMTは試料の厚みを数百nmにする必要があること、アーティファクト(偽画像)が発生しやすいという問題があります。X線CTでは画像のコントラストが得にくいという問題があり、高分子材料への応用例がTEMTなどに比べると少ない状況です。また、ゴム材料の場合、X線曝露による加硫反応によって物性変化を起こしてしまうといった問題もあります。近年、画像センサの感度が改善されてきたこと、高速撮影技術が向上したことに伴い、短い時間のX線露光でコントラストのあるCT像の取得が可能となりました。

そこで、研究チームはシンクロトロン放射光施設を利用し、微小な変形場での微粒子充てんゴム材料のマイクロX線CTを実施しました。X線CT装置に搭載可能な小型引張試験機を開発し、引張試験によるマクロな変形挙動を同時に評価しました。マクロな評価から弾性変形領域と判断できる変形領域において、変形量に応じてミクロな変形は不均一になっていくことが明らかになりました。

振動分野では減衰特性は動的条件下で確認されるパラメータです。一方で、材料開発の視点から見ると構造が決まった段階で減衰特性は決まっているはずなので、静的な変形であっても何か違いが現われるだろうという期待からマイクロX線CTによる計測を試みました。

現在、動的X線CTの実施を試みています。メソスケールでの内部構造の変形挙動が明らかになり、充てん剤に関わる制御因子と減衰特性の関係が明らかになることを期待しています。

本研究はJSPS科研費(JP16K18041,JP18K13715)の助成を受けたものです。また、文部科学省私立大学戦略的研究基盤形成支援事業(平成25年~平成29年、同志社大学)の支援を受けました。ここに記して謝意を表します。

Researcher Profile

| Name | Masami Matsubara |

|---|---|

| Affiliation | Department of Mechanical Engineering |

| Title | Associate Professor |

| Fields of Research | Mechanical Dynamics / Vibration Dynamics |

ここでコンテンツ終わりです。