ここからコンテンツです。

Toward development and mass production of all-solid-state lithium Ion batteries

Atsunori Matsuda

Lithium ion batteries (LIBs) are widely used as power sources for smartphones and laptop computers. They are also essential for certain types of transport such as electric vehicles (EVs) as well as for emergency power supplies in the event of a disaster. Unsurprisingly then, there is fierce global competition to develop LIBs with even higher energy density and better performance. However, there is a major drawback with the current generation of LIBs, in that a flammable organic electrolytic solution is used for the electrolyte, creating is a risk of leakage and ignition. Due to this, the drive to develop safer materials has become an urgent matter.

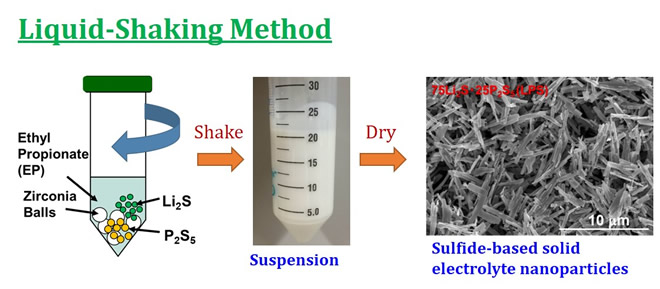

It is in this context that the next-generation LIBs are being developed as all-solid-state batteries using flame-retardant solid-state electrolytes and boasting excellent stability. As a part of this drive, Professor Atsunori Matsuda has proposed a "liquid-phase shaking method" synthesis process. Since this method allows for solid-state electrolytes to be easily produced in large quantities, it has been widely recognized as a major contribution to the development and mass production of all-solid-state LIBs.

Interview and report by Madoka Tainaka

Expectation for all-solid-state lithium ion batteries is increasing against the backdrop of the uptake of EVs

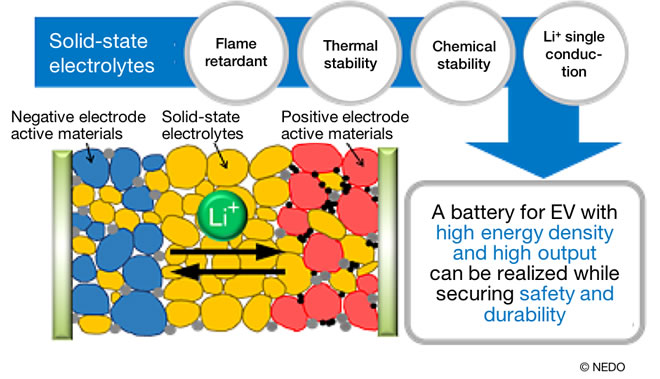

Currently, the rapid uptake of EVs is driving the urgent need for practical all-solid-state LIBs that realize both high energy density and safety. Toyota stated that it will replace all its models with hybrid cars or EVs by the end of 2025, and it is expected that the shift to EVs will advance rapidly all over the world in the future.

In light of these circumstances, in June 2018, the New Energy and Industrial Technology Development Organization (NEDO) launched a research and development project on the early realization of all-solid-state LIBs. In addition to solving issues for the commercialization of all-solid-state LIBs, topics such as development of mass-production processes and evaluation of suitability for onboard batteries, etc. will be tackled.

The project is being carried out by 23 major companies in Japan such as automobile, battery, and material manufacturers, 15 universities and public research institutes including Toyohashi University of Technology (TUT), and will be based at the Consortium for Lithium Ion Battery Technology and Evaluation Center (LIBTEC). It is an "All Japan" initiative that will strengthen links between industries.

Professor Matsuda of TUT, who is involved in the development of solid-state electrolytes - the key material for batteries - explains the advantages of all-solid-state LIBs.

"It is not easy to move ions with large mass in solids. However, if the electrolyte that is sandwiched between the positive and negative electrodes can be made into a solid, the thermal and chemical stability increases, and safety is dramatically improved since the battery becomes more difficult to burn. Moreover, sulfide-type solid-state electrolytes, which use lithium sulfide (Li2S) as the main component, demonstrate high conductivity comparable to that of an organic electrolyte and are capable of a lithium ion transference ratio of 100%. In other words, because we can carry only the ions that we want, we can make a big contribution to improving the energy density."

"All Japan" initiative for early practical application

This NEDO project is the successor to the ALCA-Specially Promoted Research for Innovative Next Generation Batteries (ALCA-SPRING) project, which was implemented by the Japan Science and Technology Agency (JST) under the Ministry of Education, Culture, Sports, Science and Technology, and ran from 2013 to 2017. Under ALCA-SPRING, all activities were focused on the goal of developing next generation batteries. These ranged from battery design and material development for positive and negative electrodes and electrolytes, to evaluation and analysis. The new project has been transferred to NEDO under the auspices of the Ministry of Economy, Trade and Industry. This exceptional initiative is being framed as a second phase project on all-solid-state LIBs, with the goal of putting the research to practical use.

While Toyota was the only company that participated in the first phase, several major Japanese manufacturers have come together for the second phase, demonstrating the enthusiasm for betting on this research as an "All Japan" national effort.

"Japanese manufacturers used to hold more than 90% of the global LIB market share, but this figure has currently dropped to one third. The collective will to avoid the same thing happening with all-solid-state LIBs explains the strong backing for the research. That's why, for this project, we are not only pursuing technology and manufacturing processes, but also working on battery testing and evaluation methods so that Japanese methods will become international standards."

"Liquid-phase shaking method" opens the way to practical use and mass production

One of the most significant challenges to the practical application and upsizing of all-solid-state LIBs is production of solid electrolytes at large scale and low cost.

Responding to this challenge, Professor Matsuda succeeded in preparing lithium thiophosphate (LPS) by mixing the starting material in ester organic solvent using the liquid-phase shaking method, performing centrifugation, and then reducing the pressure and drying. Previously, it was necessary to synthesize solid electrolytes by stirring a powder for a long time using a planetary ball mill.

"With this method, it becomes possible to synthesize sulfide-based solid electrolytes in a short time and with less energy. In addition, the particles of the obtained solid electrolyte are extremely small "nano size" (about 50 to 100 nm), whereas those produced with a conventional planetary ball mill are about 5 μm. By sandwiching this electrolyte between the positive and negative electrode active materials and press molding to form a compact, it mixes moderately with the active materials of both electrodes and a good interface is obtained," says Professor Matsuda.

To synthesize LPS using the conventional milling method, it is necessary to continue mixing with high energy for a long time. It is also difficult to synthesize in large quantities at once. But with the liquid-phase shaking method, LPS can be prepared in a suspended state, so it can be cheaply produced in large quantities in existing chemical plants in the future.

As many countries struggle to develop sulfide-based all-solid-state LIBs, the particular reason why Professor Matsuda's manufacturing process is drawing attention is said to be its low total cost and high efficiency.

Professor Matsuda summarized his outlook on the challenges ahead as follows, "Of course, many countries are seeking mass production using the liquid-phase method, but as an academic, I want to challenge myself to do everything I can. By pursuing this principle, I hope to contribute to making better quality electrolytes and safe, high-performance all-solid-state batteries."

Perfecting the liquid-phase method for future batteries

According to the market research company Fuji Keizai, mass production of all-solid-state batteries for EVs will begin in the 2020s, and by 2035 the world market will grow to 2,787.7 billion yen. Within this market, the market for sulfide-based all-solid-state batteries will account for the majority at 2,120 billion yen. This analysis backs up the government's decision to support this project on a national basis.

Meanwhile, Professor Matsuda is looking even further into the future of batteries.

"Metal-air batteries are one of the possibilities to come after LIBs. Compared with sulfide, they can be made of more stable materials, but at present they are difficult to manufacture, and we cannot yet see a path to their widespread use. However, it would be easy to manufacture an electrolyte that makes and moves OH- (hydroxide ions) from air if the liquid-phase method is used. In fuel cells, protons (H+) need to be moved, and the liquid-phase method also holds the key to this. I expect that I will be able to utilize my experience as a specialist in materials who has developed functional materials using liquid-phase in various ways from now on."

If the performance of batteries improves, it will not only help to make EVs widespread but will also enable distributed power generation and storage, which will contribute to solving the global energy problem. We are looking forward to the further progress of Professor Matsuda's future research.

Reporter's Note

Professor Matsuda says that he is proud of his 6th Dan level in kendo. When he was in elementary school, he watched the TV drama "Ore Wa Otoko Da!" (I am a man!) and admired Kensaku Morita who portrayed the captain of a kendo club, and so he started kendo as a club activity from junior high school. After that, he belonged to his high school and university kendo clubs, and after getting a job he was involved in the Tsukuba University friends of kendo association and the kendo club alumni group at Osaka Prefecture University, his alma mater. Currently, he serves as an advisor to the Toyohashi University of Technology kendo club. He also taught kendo to his three children.

"Something you cultivate for over 40 years will not decline easily. I think it is meaningful to persevere at something. Currently, I am challenging myself to reach 7th Dan," says Professor Matsuda enthusiastically.

Professor Matsuda also began synthesis of functional materials using the liquid-phase method as his graduation research when he was an undergraduate. He has worked on various themes, but by tackling problems based on liquid-phase, it has led to significant research results. This is truly "the power of perseverance." Please do your best to reach 7th Dan!

全固体リチウムイオン電池の開発と量産化をめざして

スマートフォンやノートパソコンなどの電源として広く普及しているリチウムイオン電池(Lithium Ion Battery=LIB)。電気自動車(Electric Vehicle=EV)などの移動体の電源や災害時の非常用電源としても不可欠であり、さらなる高エネルギー密度化・高性能化をめざして、世界中で開発競争が過熱している。しかし、現状のLIBには、電解質に可燃性の有機電解液が使用されていて、液漏れや発火の危険性が伴うことから、より安全な材料への転換が急務となってきた。

そこで現在、次世代のLIBとして開発が進められているのが、難燃性の固体電解質を用いる安定性に優れた全固体LIBだ。特に、松田厚範教授が提案する合成プロセス「液相加振法」を用いれば、固体電解質が簡易な方法で大量に製造することが可能になるため、全固体LIBの開発と量産化に寄与するとして大きな注目を集めている。

EVの普及を背景に、全固体リチウムイオン電池への期待が高まる

現在、高いエネルギー密度と安全性の両方を実現する全固体LIBの実用化が急がれる背景には、EVの急速な普及がある。トヨタ自動車が2025年の終わりまでに全車種をハイブリッドカーないしはEVに置き換えると宣言したように、今後は世界中で急速にEVシフトが進むと予想される。

こうした状況を受けて、2018年6月、新エネルギー・産業技術総合開発機構(NEDO)は、全固体LIBの早期実用化に向けて、研究開発プロジェクトをスタートした。全固体LIBの製品化に向けた課題解決に加え、量産プロセスの開発、車載用電池としての適合性の評価などを実施するという。

参画するのは、自動車メーカーのほか、蓄電池・材料メーカーなどの日本の主要企業23社と、豊橋技術科学大学をはじめとする大学・公的研究機関15法人で、技術研究組合リチウムイオン電池材料評価研究センター(LIBTEC)を拠点に、業種を超えた連携を強化しながらオールジャパンで進めている。

当プロジェクトにおいて、電池のキーマテリアルである固体電解質の開発を手がける本学の松田教授は、全固体LIBのメリットを次のように説明する。

「質量の大きいイオンを固体の中で動かすのは容易ではありません。しかし、正極と負極に挟まれた電解質が固体になれば熱的にも化学的にも安定性が高まり、燃えにくくなることから安全性が格段に上がります。しかも、硫化リチウム(Li2S)を主成分とする硫化物系固体電解質であれば、有機電解液に匹敵する高い導電率を示し、リチウムイオン輸率は100%。つまり、欲しいイオンだけを運ぶことができることから、エネルギーの高密度化に大きく貢献できるというわけです」

早期実用化に向けた、オールジャパンの取り組み

実は当プロジェクトは、文部科学省所管の科学技術振興機構(JST)で実施された先端的低炭素化技術開発 - 次世代蓄電池(ALCA-SPRING)研究開発プロジェクト(2013〜2017年)を引き継いだものなのだという。ALCA-SPRINGでは、次世代蓄電池の開発で、電池設計から正極・負極・電解質の材料開発、評価解析まで含めた電池システムの開発を実施。その中で、とくに実用化に期待がかかる全固体LIBについて、第2期プロジェクトとして経済産業省所管のNEDOに研究が移管されたという異例の取り組みなのだ。

第1期の参画がトヨタ自動車1社だけであったのに対して、第2期では、日本の主要メーカーが勢揃いしたように、国を挙げてオールジャパンでこの研究に賭ける意気込みが伝わってくる。

「かつて日本のメーカーは、LIB世界シェアの9割以上を占めていましたが、現在では3分の1まで落ち込んでいます。全固体LIBでは同じ轍を踏むまいと、皆が強い思いで研究に臨んでいます。だからこそ、プロジェクトの中では、たんに技術や製造プロセスを追求するだけでなく、日本の方式が国際規格になるよう、電池の試験・評価方法まで手がけているのです」

「液相加振法」で実用・量産化への道をひらく

とりわけ、全固体LIBの実用化や大型化の重要な課題の一つとなってきたのが、固体電解質の量産と低コストでの製造である。

そうした中、松田教授は、これまで遊星型ボールミルを用いて粉体同士を長時間かき混ぜて合成していた固体電解質を、液相加振法という方法により、出発物質をエステル系有機溶媒中で混ぜ、これを遠心分離したのち、減圧、乾燥することでチオリン酸リチウム(LPS)を作製することに成功した。

「これにより、短い時間と少ないエネルギーで硫化物系固体電解質を合成することが可能になりました。しかも、得られる固体電解質の粒子は、従来の遊星型ボールミルでつくるものが5μm程度であるのに対して、ナノサイズ(100〜50nm程度)と非常に小さい。これを負極活物質と正極活物質の間に挟んで、加圧成形して圧粉体にすることより、両極の活物質と適度に混ざり、良好な界面が得られます」と松田教授は話す。

LPSをつくる場合、従来のミリング法で合成しようとすると、長時間、高いエネルギーをかけながら混ぜ続ける必要がある。また、一度に大量に合成することも難しい。一方、液相加振法であれば、懸濁液の状態で調製できるため、将来、既存の化学プラントで安価で大量につくることができるのだという。

各国が硫化物系全固体LIBの開発にしのぎを削るなか、とくに松田教授の製造プロセスが注目される理由は、トータルコストの安さと効率の良さだという。

「もちろん、各国が液相法による量産化を模索していますが、やはりアカデミアだからこそできることにチャレンジしたい。原理を追究することで、より良質な電解質と安全で優れた全固体電池をつくることに貢献できればと思っています」と、松田教授は展望を語った。

未来の電池へ向けて、液相法を究める

ところで、市場調査会社の富士経済によれば、全固体電池はEV向けに2020年代から量産が始まり、2035年には2兆7877億円まで一気に世界市場が膨らむと予測している。うち、硫化物系全固体電池は2兆1200億円とその大半を占める。今回のプロジェクトに、国を挙げて取り組むのも頷ける。

一方で、松田教授は、さらにその先の電池の未来まで視野に入れている。

「ポストLIBの一つに金属空気二次電池があります。硫化物に比べて、より安定した材料でつくることができますが、現状は製造が難しく、普及の見通しは立っていません。しかし、空気からOH−(水酸化物イオン)をつくって動かす際の電解質も液相法であればつくりやすい。また、燃料電池ではプロトン(H+)を動かす必要がありますが、これも液相法がカギを握ります。これまで、材料屋として、液相で機能性材料を開発してきた経験が、今後もさまざまに活かせるでしょう」

蓄電池の性能が上がれば、EVの普及のみならず、発電や蓄電の分散化を可能にし、地球規模のエネルギー問題の解決にもつながる。今後の松田教授のさらなる研究の進展に期待したい。

(取材・文=田井中麻都佳)

取材後記

剣道六段の腕前を誇るという松田教授。小学生の頃、テレビドラマ『おれは男だ!』で森田健作が扮する剣道部キャプテンの主人公に憧れ、中学から部活で剣道を始めたという。以来、高校、大学と剣道部に所属して、就職後も筑波大学剣友会や母校・大阪府立大学剣道部OB会で活動。現在も豊橋技科大剣道部顧問を務める。三人のお子さんにも剣道を教えた。

「40年以上かけて培ったことは簡単には衰えません。続けることに意味があるということでしょうか。現在、七段に挑戦中です」と松田教授は意気込む。

液相法による機能性材料の合成も卒業研究として学部生の頃から始めた。テーマはさまざまだが、液相をベースに一途に取り組むことで、大きな研究成果に結びついてきた。まさに「継続は力」。七段への挑戦、がんばってください!

Researcher Profile

Dr. Atsunori Matsuda

Dr. Atsunori Matsuda studied until master’s course at Osaka Prefecture University, Japan. After graduate from the university, started his career at Nippon Sheet Glass Company Ltd., and received his PhD. degree in 1992 from Osaka Prefecture University. Then, he was engaged in a research as a lecturer at Osaka Prefecture University from 1997 to 2000. Currently, he is a professor in the Department of Electrical & and Electronic Information and a vice president at Toyohashi University of Technology. His research interests are Inorganic Materials Science, Sol-Gel Method, and All-solid-state battery.

Reporter Profile

Madoka Tainaka is a freelance editor, writer and interpreter. She graduated in Law from Chuo University, Japan. She served as a chief editor of "Nature Interface" magazine, a committee for the promotion of Information and Science Technology at MEXT (Ministry of Education, Culture, Sports, Science and Technology).

ここでコンテンツ終わりです。