ここからコンテンツです。

Utilizing Digital Fabrication Tools to Enjoy Designing Chairs with Parents and Children

Open the possibilities of woodworking to local communities with digital fabrication tools by means of a computer-aided design system that anyone can easily operate By Akihiro Mizutani

The 3D CAD system, which can design 3D chairs by a simple operation, developed by Mizutani, a lecturer of the Department of Architecture and Civil Engineering, is developed in such a way that anyone can easily operate it. The chair-making workshop was designed so that parents and children can enjoy making chairs together using the digital fabrication of the system. In the chair-making workshop: (1) The parents and children design the original chair that matches the child's figure, (2) the miniature model is processed and produced with the laser cutter, and (3) the actual product is processed with the CNC router. This ICT-applied technology could revolutionize aspects of future society. We expect a personal manufacturing revolution to open up new possibilities for the local community, applying such digital fabrication tools.

In recent years, digital fabrication tools, such as laser cutters and CNC routers, which had previously only been used by industry, have been developed into individual manufacturing facilities as tools available for personal use. Diffusion of such digital fabrication has dramatically changed the opportunities for manufacturing by individuals. It is also becoming apparent that the creation of a community centered on manufacturing can be carried out by networking on the Web and SNS. Our activities are aimed at building regional communities where manufacturing and community formation is actively performed using such digital fabrication. We designed chair making workshops specifically focused on children and their guardians with the goal of targeting citizens who have had little involvement in manufacturing and digital fabrication so far.

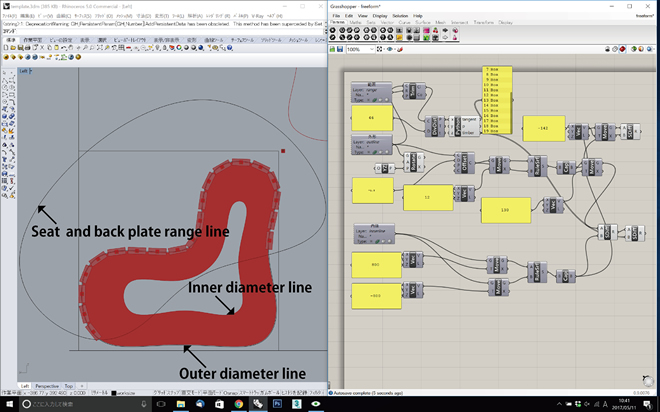

In the chair-making workshop: (1) The parents and children design the original chair that matches the child's figure, (2) the miniature model is processed and produced with the laser cutter, and (3) the actual product is processed with the CNC router. The original chair is designed and processed using a 3D CAD system (Fig. 1), which can design a 3D shaped chair through a simple operation I developed.

This unique 3D CAD system has been devised so that anyone can operate it easily, and in the chair-making workshop, parents and children can enjoy making a digitally fabricated chair using that system. Specifically, it is possible to design a 3D chair simply by manipulating the three lines that determine the elevation shape: the inner diameter line, the outer diameter line, and the seat surface/back plate range line. Normally, in order to manufacture something by digital fabrication, you need to first acquire basic techniques such as how to operate the 3D CAD. This kind of hurdle tends to lead to people giving up before they ever get to the fun part of actual design and manufacture. This workshop aims to overcome such hurdles by going the opposite way from the normal process, and starting with the pleasurable aspects of design, processing and production,. By making the experience more accessible and enjoyable, it is hoped that we can widely disseminate manufacturing by digital fabrication.

Complex curve shape processing and fitting parts in free 3D shapes are difficult processing even for craftsmen, but with digital fabrication tools, even beginners without professional knowledge and skills can process them. Details of the fitting parts, uniquely determined by the design and the size of the wood used, can be generated semi-automatically by using the 3D CAD system (Fig. 2). In other words, it is possible to operate it without having to bother too much with the bulk of the simple repetitive work, which relies on the machines’ strong point of accurate processing by numerical control. This allows people more energy to focus on creativity and fine handwork, our forte as human beings. What is special about our activity is the degree to which it makes previously remote technology so accessible, such as advanced woodworking production, digital fabrication and the independently-developed 3D CAD system.

We expect that the experiences at the chair-making workshop applying this digital fabrication will become the first step toward constructing local manufacturing communities, and the accumulation of these small steps will eventually become a major force connecting society as a whole. Technology using ICT has opened the doors to the future. We believe that an individual centred manufacturing revolution, applying such digital fabrication technology, will open up new possibilities for local communities.

A part of this activity was supported by Toyohashi City’s next-generation manufacturing R&D promotion subsidiary aid.

デジタル・ファブリケーション技術を活用して、親子で椅子のデザインを楽しもう

誰でも簡単に操作できるコンピュータ設計支援システムにより、デジタル工作機器による木工ものづくりと地域コミュニティの可能性を開くBy 水谷 晃啓

水谷講師が開発した、単純な操作で3D形状の椅子のデザインが可能な3DCADシステムは、誰でも簡単に操作することができるよう工夫されています。椅子づくりワークショップはそのシステムを用いることでデジタル・ファブリケーションを通じた椅子づくりを親子で楽しみながら行えるように考案されています。椅子づくりワークショップでは、①子供の体形に合ったオリジナル椅子のデザインを親子で行い、②レーザーカッターでミニチュア模型の加工・製作を、③CNCルータで実物の加工・製作を行います。ICTを応用した技術が未来の社会を切り開いてきておりますが、こうしたデジタル・ファブリケーション技術を応用した個人のものづくり革命が、地域コミュニティの新たな可能性を切り開いていくことを期待しています。

近年、レーザーカッターやCNCルータなど、これまで工場で用いられてきたデジタル加工機が、個人利用が可能なツールとして各地のものづくり施設に整備されはじめました。こうしたデジタル・ファブリケーションの普及は、個人のものづくりの機会を劇的に変化させました。また、インターネットやSNSを通じてこのような個人のものづくりの機会がネットワーク化されることで、ものづくりを核としたコミュニティの形成が行わることがわかってきています。私達の活動は、こうしたデジタル・ファブリケーションを用いたものづくり、コミュニティ形成が積極的に行われる地域社会の構築をめざしたものです。特にこれまでものづくりやデジタル・ファブリケーションに関わりが少なかった市民を対象にすべく、子供たちとその保護者に焦点を合わせ、椅子づくりワークショップを展開しています。

椅子づくりワークショップでは、①子供の体形に合ったオリジナル椅子のデザインを親子で行い、②レーザーカッターでミニチュア模型の加工・製作を行い、③CNCルータで実物の加工・製作を行います。オリジナル椅子のデザインと加工は、私が開発した、単純な操作で3D形状の椅子のデザインが可能な3DCADシステム(Fig.1)を用いて行います。この独自の3DCADシステムは誰でも簡単に操作することができるよう工夫されており、椅子づくりワークショップは、そのシステムを用いることでデジタル・ファブリケーションを通じた椅子づくりを親子で楽しみながら行えます。具体的には立面形状を決定する内径ライン、外径ライン、座面・背板範囲ラインの三つのスプラインを自由な形状に操作するのみで3D形状の椅子のデザインを行うことが出来ます。通常、デジタル・ファブリケーションを通したものづくりを行うためは、デザインや製作加工の前に、3DCADの操作方法といった基礎技術の習得が必要となります。このことが少なからずものづくり参画のハードルを高いものとし、また本来の目的であり愉しみであるデザインや製作加工に到達する前に修練の道を諦めてしまうという事態を引き起こしていました。ここではデジタル・ファブリケーションを用いたものづくりを広く普及させることを目的に、コンピュータ支援を積極的に活用して、通常のプロセスとは反対のデザインや加工、製作の愉しみから始められるようになっています。

自由な立面形状に含まれる複雑な曲線形状加工や嵌合(かんごう)部分などは職人でも難しい加工ですが、デジタル工作機器を用いれば、専門的な知識や技術がない初心者であってもその加工を実現することができます。デザインと使用する木材のサイズによって一義的に決まる嵌合部分のディテールは、3DCADシステムにより半自動でその加工データの生成を行うことができます(図2)。つまり、機械が得意とする単純な繰り返し作業や数値制御による正確な加工について、複雑なことを考えずに操作することが可能であり、人間が得意とする創造性やきめ細やかな手仕事に注力する余力を生むことができます。独自開発した3DCADシステム同様に、高度な木工製作やデジタル・ファブリケーションというこれまで限定的であった個人の愉しみを、より多くの方が気軽に参画できる技術として提供した点にこの活動の高い独創性があります。

このデジタル・ファブリケーションを応用した椅子づくりワークショップでの体験が、地域社会におけるものづくりコミュニティ構築の第一歩となり、その小さな一歩の積み重ねがやがて大きな力となって地域全体がつながっていくことを期待しています。ICTを応用した技術が未来の社会を切り開いてきておりますが、こうしたデジタル・ファブリケーション技術を応用した個人のものづくり革命が、地域コミュニティの新たな可能性を切り開いていくと考えています。

本活動の一部は豊橋市次世代ものづくり研究開発促進事業補助金により実施いたしました。

Reference

朝日新聞「豊根杉でマイ椅子を作ろう」2017年5 月27日付朝刊、三河13(31)

Researcher Profile

| Name | Akihiro Mizutani |

|---|---|

| Affiliation | Department of Architecture and Civil Engineering |

| Title | Lecturer |

| Fields of Research | Architectural Design / Architectural Planning/ Urban Design |

ここでコンテンツ終わりです。