ここからコンテンツです。

Robotic Support for Regional Agriculture

Automating labor-intensive and costly processes of harvest in greenhouse horticulture By Jun Miura

An academia-industry collaborative team is now developing harvest support robots for greenhouse horticulture. The target crops for these particular robots are green perilla and cut flowers, which are very popular crops in local agriculture. These robots are expected to be commercialized in the near future.

Labor shortage has become one of the most serious problems in Japanese agriculture as the portion of elderly workers in agriculture significantly increases. Producing high quality agricultural products at a reduced production cost is another issue to resolve if we wish to make Japanese agriculture competitive in the world market in this age of international trade liberalization. Aichi prefecture and its East Mikawa region, where Toyohashi University of Technology (TUT) exists, are famous for producing a large variety and amount of agricultural products, especially in greenhouse horticulture. An academia-industry collaborative team is now carrying out a project to develop robots for harvest support, which are expected to contribute to this regional agriculture.

The team is composed of TUT researchers and engineers from industry (Sinfonia Technology Co. Ltd. and KER Co. Ltd.). The leader of the research project is Prof. Miura from the Department of Computer Science and Engineering. He explains that, “Since completely automated harvesting is still difficult to realize even with the state-of-the-art robotics and computer vision technologies, we analyzed the process of harvesting crops, and designed robots that can perform certain parts of that process so as to significantly improve its cost effectiveness.”

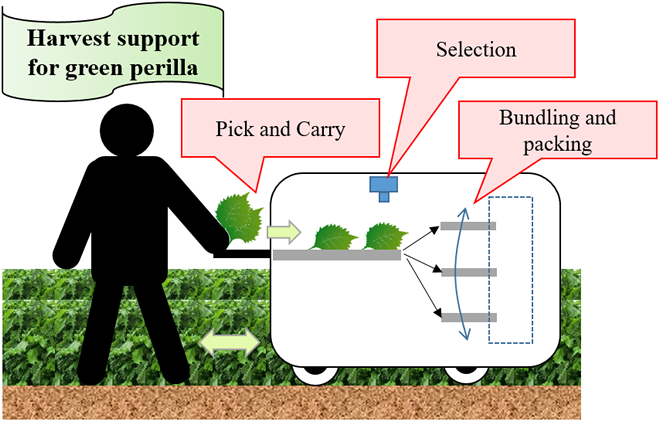

One of the target crops is green perilla ("Ooba" in Japanese), for which Aichi prefecture has over 60% share in Japan. Fig. 1 shows the steps in harvesting green perilla from reaping and packing. The most costly and time-consuming parts are selection and bundling, which are usually carried out by in-house workers. The team is developing a compact and movable robotic system that can automate these steps, using soft object handling and visual inspection technologies (see Fig. 2).

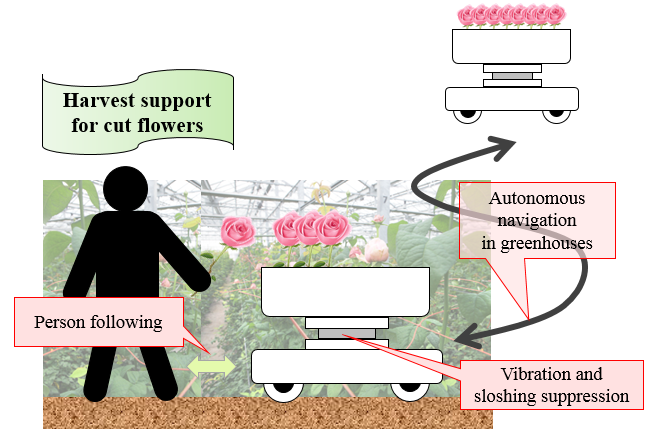

The other target is cut flower harvesting. Aichi prefecture is the biggest producer in the country of many types of flowers such as roses and chrysanthemums (kiku in Japanese). One of the key issues for improving the quality of flowers is to shorten the time between harvesting the flowers and putting them into water. For this purpose, the team is developing a mobile robot which automatically follows a worker, and is equipped with a water tank fitted with suppression control for sloshing and vibration. It also automatically returns to its station once a sufficient amount of flowers has been harvested. (see Fig. 3).

Prof. Miura says, “Resolving the problems of Japanese agriculture is an important and urgent task, and we believe robotics technologies will contribute to it. Our strong academia-industry collaborative team is now working hard to realize commercially-available products in the near future.”

This project is supported by Knowledge Hub Aichi, Priority Research Project (Second Term) PR4, Aichi Prefecture, Japan.

ロボット技術による地域農業の支援

施設園芸作物の収穫作業の一部を自動化し,人手不足と高コスト化に対処するBy 三浦 純

産学が連携して施設園芸作物の収穫支援ロボットを開発しています。地域の主要作物である大葉と切り花を対象とし、近い将来の実用化を目指しています。

日本では農業従事者の高齢化に伴い人手不足が深刻な問題となっています。また、貿易自由化の流れの中で、高品質の農作物を省コストで生産することが世界との競争を勝ち抜くために必要となっています。豊橋技術科学大学のある愛知県、そして東三河地区は農業の盛んな地域として有名で、特に施設園芸作物が多く生産されています。産学連携のプロジェクトにより収穫支援のロボットを開発し、地域農業に貢献することを目指しています。

ロボットの開発は、本学(研究リーダー:情報・知能工学系 三浦教授)とシンフォニアテクノロジー(株)および(株)ケーイーアールの産学連携チームにより進められています。現在の最先端のロボットや画像認識の技術を用いたとしても収穫の完全自動化は未だ難しい問題です。そこで、作物収穫の過程を分析した結果から、省力化に寄与し、また作物の競争力を高めるために重要な手順を自動化するロボットを設計し、開発を行っています。

対象とする作物の一つは大葉であり、愛知県の生産高は全国の6割を超えています。図1に大葉の摘み取りからパッキングまでの過程を示します。最もコストと時間がかかる過程は大葉の選別と結束であり、ほとんどの場合内職で行われています。柔軟物体の操作技術と画像による品質評価技術を基に、それらの過程を自動化することのできる可搬型のロボットシステムを開発しています(図2参照)。

もう一つの対象は切り花の収穫支援です。愛知県はバラや菊など多くの花の生産高が全国一です。花の鮮度を保つには摘んでからできるだけ早く水につけることが重要です。そこで、水槽を搭載し、越水や振動を抑制しつつ人に追従して動き、満杯になったら自動的に集荷場所に移動するロボットを開発しています(図3参照)。

日本の農業が抱える問題を解決することは喫緊の課題であり、ロボット技術がその助けになると考えています。近い将来に商品として市場に出せるように、産学で強力なタッグを組んで研究開発を進めています。

本プロジェクトは知の拠点あいち重点研究プロジェクト(II期)の支援のもとに行われています。

Researcher Profile

| Name | Jun Miura |

|---|---|

| Affiliation | Department of Computer Science and Engineering |

| Title | Professor |

| Fields of Research | Intelligent Robotics / Robot Vision / Artificial Intelligence |

ここでコンテンツ終わりです。