ここからコンテンツです。

Unveiling the electron's motion in a carbon nanocoil

Development of a precise resistivity measurement system for quasi-one-dimensional nanomaterials using a focused ion beam By Yoshiyuki Suda

Yoshiyuki Suda, in cooperation with researchers at the University of Yamanashi, the National Institute of Technology Gifu College, and Tokai Carbon Co., Ltd., has discovered how the electrical resistivity of carbon nanocoils (CNCs) depends on their geometry. The finding, which required development of a new resistivity measuring apparatus, paves the way for CNC-based nanodevices ranging from electromagnetic wave absorbers to nano-solenoids and extra-sensitive mechanical springs.

Carbon nanocoils (CNCs) are an exotic class of low-dimensional nanocarbons whose helical shape may make them suitable for applications such as microwave absorbers and various mechanical components such as springs. Typical thicknesses and coil diameters of CNCs fall within the ranges of 100–400 nm and 400–1000 nm, respectively, and their full lengths are much larger, on the order of several tens of micrometers. Despite earlier pioneering work, the relationships between the geometric shape of natural CNCs and their mechanical and electrical properties, particularly the electrical resistivity, are not well understood.

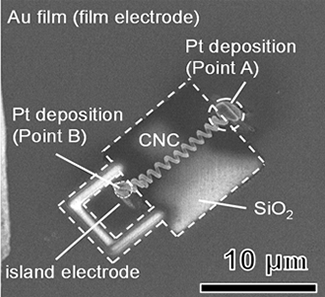

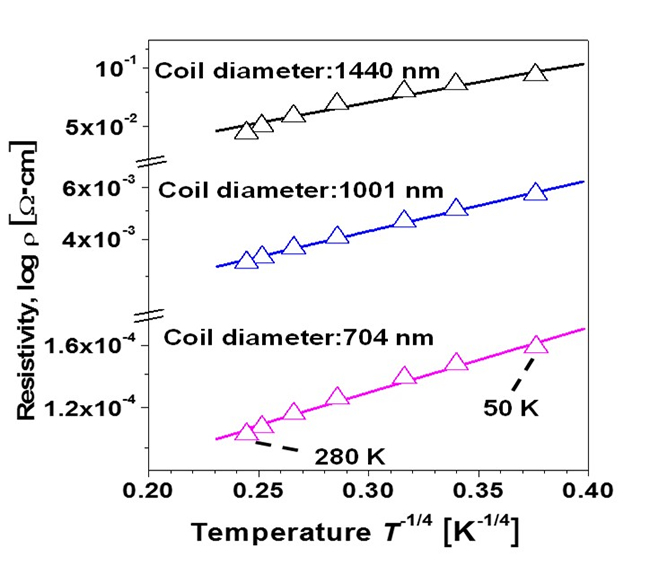

Now, Yoshiyuki Suda and his colleagues at Toyohashi University of Technology, University of Yamanashi, National Institute of Technology - Gifu College, and Tokai Carbon Co., Ltd. have established that the resistivity of CNCs increases with coil diameter. To make this discovery, it required the development of a precise resistivity measurement method, using a focused ion beam (FIB) and nanomanipulator technique to select a sample CNC with the desired coil geometry and then make firm electrical connections to the instrument’s electrodes. All the resistivity data obtained with CNCs fits nicely with the curves predicted by a theory known as variable range-hopping (VRH), which is suitable for disordered materials at low temperatures.

The research shows that the interior of the nanocoil contains material that affects its electrical properties. The scientists examined 15 individual CNCs, and three CNCs that had been artificially-graphitized to give them lower resistivity (G-CNCs). Although the resistivity of the CNCs increased with coil diameter, it was almost unchanged for the G-CNCs. As a consequence, for the CNCs with the largest diameters, the resistivity was almost two orders of magnitude larger than that of the graphitized versions.

This large discrepancy in the resistivity between CNCs and G-CNCs indicates a significant structural complexity inside the CNCs. The results imply that the interior of CNCs with large coil diameter is filled with a highly-disordered carbon network that consists of many small regions (known as sp2 domains) embedded in a sea of amorphous carbon. To verify this theory, the temperature dependence of the resistivity between 4 K and 280 K was examined. The resistivity data obeyed two different versions of the VRH theory; the regime in the temperature range of 50–280 K was found to be the so-called Mott-VRH version, while that in the range of 4–20 K was the Efros–Shklovskii-VRH version. Interestingly, the resistivity curves shifted smoothly between regimes as the coil diameter was changed.

"We first observed this behavior three years ago. Thanks to the efforts of two my students, we were able to include the resistivity data for G-CNCs and straight carbon nanofibers (CNFs), and compare them to the data for the CNCs", explains Associate Professor Yoshiyuki Suda, "I am very grateful to Prof. Hiroyuki Shima and Dr. Tamio Iida for joining this study. Together, we obtained the low-temperature measurement data and discussed it using the VRH theory. Eventually, we came to the conclusion that this behavior is a unique phenomenon for CNCs and can be fitted by VRH."

The first author, Master’s course student, Yasushi Nakamura, commented on how they went beyond the CNC resistivity measurements of other groups. "It was a long and challenging task. I had to prepare many single CNC samples using a focused ion-beam apparatus. Our finding was achieved by establishing a precise measurement system using a scanning electron microscope and acquiring resistivity data for many single CNCs."

The group’s present results on resistivity are in qualitative agreement with their previous findings on the mechanical properties of CNCs: Tensile load experiments showed that their shear modulus increases with coil diameter. The positive correlation between the shear modulus and coil diameter is possibly caused by the fact that in large-diameter CNCs, the population of sp2 domains, which are fragile against shear stress, is reduced in comparison to small-diameter CNCs.

These results imply that, with nanocoils, the resistance as well as the inductance are defined by geometric factors. In particular, coil diameter, pitch, and length are important. The correlation found can be used to improve control over the peak frequency of electromagnetic wave absorption, in which a particular range of frequencies (~GHz) is absorbed, dependent on the impedance properties.

These findings pave the way for CNC-based nanodevices, ranging from electromagnetic wave absorbers to nano-solenoids and extra-sensitive mechanical springs.

This work was partly supported by

- JSPS KAKENHI Grant Numbers 24360108, 25390147, and 15K13946.

- The Toyota Physical and Chemical Research Institute.

Reference

Yasushi Nakamura, Yoshiyuki Suda, Ryuji Kunimoto, Tamio Iida, Hirofumi Takikawa, Hitoshi Ue, and Hiroyuki Shima (2016). Precise measurement of single carbon nanocoils using focused ion beam technique, Applied Physics Letters, 108, 153108. 10.1063/1.4945724

カーボンナノコイルの電子輸送機構の解明

集束イオンビーム装置を利用した準一次元ナノ材料のための精密な抵抗率測定系の開発電気・電子情報工学系 須田善行准教授は、山梨大学、岐阜高専、東海カーボンの研究者と共同で、初めてカーボンナノコイル(CNC)の電気抵抗率とコイル形状との関係を明らかにしました。この研究成果は新たな抵抗率測定系を開発することによって初めて成し遂げられました。研究での発見はCNCを用いたナノデバイス―電磁波吸収体、ナノソレノイド、超高感度コイルばね―への道を開くものとなります。

カーボンナノコイル(CNC)はらせん構造をもつ低次元カーボンナノ材料です。典型的なCNCは、ファイバー直径が100から400ナノメートル、コイル直径が400から1000ナノメートルであり、全長は数十マイクロメートルあります。CNCのらせん構造は様々な応用-電磁波吸収体やエネルギーデバイスの材料-が期待されています。こうした応用のために、CNCの機械的・電気的特性を明らかにすることは重要です。いくつかの先駆的な研究例はあるものの、CNCの形状とその電気抵抗率との関係は未解明のままでした。

豊橋技術科学大学、山梨大学、岐阜高専、東海カーボンの研究者らはCNCの電気抵抗率がコイル直径によって増大することを見出しました。それにあたり、集束イオンビーム装置を使用してCNC抵抗率の精密な測定系を開発しました。その測定系は、所望のコイル形状をもつCNCを測定用試料として選択し、測定用電極とそのCNCとを強固に接触させることができるものです。測定されたCNCの電気抵抗率データはバリアブルレンジホッピング(VRH)理論に基づく曲線とよい一致を示しました。

開発した装置により、15本の単一CNCと3本の黒鉛化処理CNC(G-CNC)とを測定し、CNCの電気抵抗率がそのコイル径によって増加することを見出しました。一方、G-CNCの電気抵抗率はコイル径によらずほぼ一定でした。最大のコイル径をもつCNCの電気抵抗率はG-CNCの電気抵抗率よりおよそ2桁高い値を示しました。CNCとG-CNCとの間の電気抵抗率の大きな差はCNC内部の構造に起因するものと考察されました。

本研究の一部は、科研費24360108, 25390147, 15K13946 と、豊田理化学研究所の支援を受けて実施されました。

Researcher Profile

| Name | Yoshiyuki Suda |

|---|---|

| Affiliation | Department of Electrical and Electronic Information Engineering |

| Title | Associate Professor |

| Fields of Research | Plasma Materials Engineering/Carbon Nanomaterials Processing |

ここでコンテンツ終わりです。