Research highlights

Materials science: enhancing the ductility of bulk metallic glasses

Metals exist in nature as crystals with their atoms are arranged in regular lattices. On the other hand, the atoms of so-called amorphous materials do not display any well-defined crystalline order, and often resemble the atomic structure of liquids. The most well-known of these amorphous materials is glass, but notably, rapidly cooling metals can also lead to an amorphous structure. Metals composed of more than one element are referred to as alloys, and their composition enables the possibility of creating thick samples of amorphous metals are known as bulk metallic glasses. The lack of an ordered lattice structure endows such materials with extraordinary mechanical properties, such as large reversible deformation thresholds, making them highly appealing as structural materials.

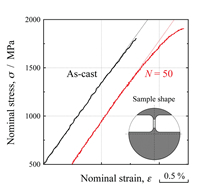

However, the amorphous nature of bulk metallic glasses severely limits their ductility - under tensile plastic strain only single shear bands are formed, leading to significant softening. Now, a team of researchers from the Toyohashi University of Technology and Tohoku University report how mechanically-induced defects can counter this limitation and enhance the ductility of bulk metallic glasses. The study describes the results of differential scanning calorimetry measurements on bulk metallic glass Zr50Cu40Al10.

The researchers discovered that the shear-induced atomic rearrangements were activated via a universal mechanism known as β-relaxation, whose energy cost depends on the material composition. Rather than altering the material, Nozumo Adachi and co-workers introduced structural defects into the sample in the form of free volumes and anti-free volumes, by high-pressure torsion. The processed bulk metallic glass underwent β-relaxation more easily, and enhanced tensile properties of up to 0.34% plastic elongation. These results show that systematic deformation of bulk metallic glasses is a promising technique for enhancing their mechanical properties without the need for composition alterations.

- Reference:

- N Adachi, Y. Todaka, Y. Yokoyama and M Umemoto.

- Improving the mechanical properties of Zr-based bulk metallic glass by controlling the activation energy for β-relaxation through plastic deformation.

- Applied Physics Letters 105, 131910 (2014)

- doi:10.1063/1.4897439

Nozomu Adachi

Fig.1:Comparison between the tensile properties of the bulk metallic glass Zr50Cu40Al10 with (red line) or without (black line) high-pressure torsion-induced defects.

Research from the Toyohashi University of Technology and Tohoku University reported how structural defects have the potential to enhance the ductility of bulk metallic glasses, one of the limitations to their use as structural materials.

Enlarge Image