ここからコンテンツです。

High-speed, high-precision positioning of stages with unknown vibration characteristics

Simple design of high-speed, ultra-precise positioning control system without dynamic model Kaiji Sato

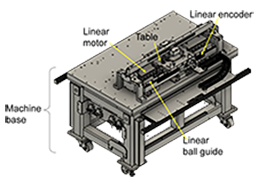

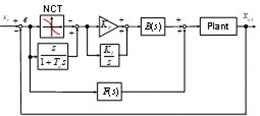

A research team led by Professor Kaiji Sato (Robotics and Mechatronics Laboratory, Department of Mechanical Engineering, Toyohashi University of Technology) revealed a method for designing with ease an ultra-precise positioning control system on the order of 10nm, even if the dynamic model and model parameters of the motion mechanism and the machine base on which it is installed are unknown. This design method provides a control system with an NCTF controller that compensates for unknown nonlinear characteristics, including frictional characteristics, to reach the target position with high speed and high precision and a vibration suppression compensator that quickly compensates for unknown vibration characteristics caused by high-speed driving. Its design is simple, and it can be designed without expertise in control system design or mechanical characteristics.

In industrial machinery such as machine tools and semiconductor manufacturing equipment, positioning accuracy and high-speed response of the mechanism are basic and important characteristics that affect the performance of the equipment. However, as the required accuracy becomes higher, the micro-dynamic characteristics caused by the mechanism and the machine base on which it is placed (which were not previously an issue) become problematic. A high-speed response generates a large reaction force, which excites each part of the mechanism. The use of active damping devices and hardware improvements are effective in suppressing micro-vibrations, but they limit the range of applications and increase costs. Using a controller that uses detailed mechanical property information is also effective, but it requires more labor and time, and requires the assistance of an expert to make adjustments. Therefore, we propose a method to effectively suppress vibration and achieve ultra-precision positioning by simple controller design and adjustment, while using the hardware as it is, without the need for mechanical property information in advance.

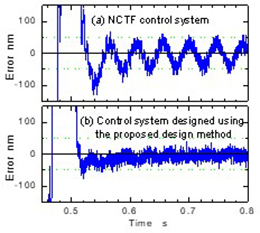

The control system consists of Nominal Characteristic Trajectory Following (NCTF) proposed by Professor Sato and the vibration suppression compensator consisting of a bandpass filter and a differential compensator, and is determined sequentially. The role of the compensator is straightforward, there are few variables to adjust, and it is easy to determine without expert knowledge. The former can be designed by incorporating an open-loop response waveform for a given input signal and adjusting the two gains step-by-step. The latter is completed by determining the two gains sequentially. The resulting control system achieves ultra-precise positioning even for mechanisms with marked nonlinear characteristics such as frictional characteristics. The latter can also be used in combination with other control systems. The effectiveness of the proposed control system design method has been demonstrated by experiments.

(a) Error of conventional NCTF control system

(b) Error of proposed control system

There is increasing demand for high acceleration, high speed, and improved accuracy in industrial machinery, making it an important issue when developing high-performance industrial machinery. This research was carried out jointly by Professor Kaiji Sato who wants to make use of the insights of his university laboratory in the real world and NEOMAX Engineering which wants to solve problems in cooperation with universities. This paper shows the achievement of the original goal and the basic results.

In the paper, the control system is adjusted to suppress two types of vibration with different properties. There are also scenarios where vibration with many different frequencies occurs, scenarios where the criteria of the vibration to be suppressed are different, and scenarios where the nature of the vibration is different. We want to increase the number of scenarios that can be addressed, and ultimately reveal how to solve these problems holistically.

Reference

Kaiji Sato, Ryouhei Hisamatsu, Kaoru Akamatsu (2023). Controller design for high-speed, ultra-precision positioning of a linear motion stage on a vibrating machine base stage control on a vibrating base. Precision Engineering,

Doi:

https://doi.org/10.1016/j.precisioneng.2022.11.008

未知の振動特性を持つステージの高速・高精度位置決め

高速・超精密位置決め制御系を力学モデルなしで簡単に設計する佐藤 海二

豊橋技術科学大学機械工学系ロボティクス・メカトロニクス研究室の佐藤海二教授らの研究チームは、運動機構やそれを設置した機械台の力学モデルやモデルパラメータが未知であっても、10nmオーダの超精密位置決め制御系を簡単に設計できる方法を明らかにしました。この設計法は、摩擦特性を含む未知の非線形特性を補償し、高速・高精度に目標位置に到達させるNCTF補償器と、高速駆動により起振される未知の振動特性を速やかに補償する振動抑制補償器をもつ制御系を提供します。その設計は簡単で、制御系設計に関する専門的知識や力学特性の情報なしで、設計することが可能です。

工作機械や半導体製造装置に代表される産業機械において、機構の位置決め精度と高速応答性は、装置性能を左右する基本かつ重要な特性です。しかし要求精度が高くなると、機構やそれを載せる機械台に起因する、従来問題とならなかった微動特性が問題となります。高速な応答は大きな反力を発生するため、機構各部を励振します。微動振動の抑制には能動制振装置の利用やハードウェア的な改良が効果的ですが、応用範囲が制限され、コストが増大してしまいます。詳細な力学特性の情報を利用したコントローラを利用する方法も有効ですが、必要な労力、時間を増大させ、専門家に調整依頼する必要があります。そこで、ハードウェアはそのまま利用し、事前に力学特性情報を必要とせず、簡単なコントローラ設計・調整により、振動を効果的に抑制し超精密位置決めを実現する方法を提示しています。

制御系は、佐藤教授が提案しているNominal Characteristic Trajectory Following (NCTF) 制御系と、バンドパスフィルタや微分補償器からなる振動抑制補償器より構成され、順次決定されます。補償器の役割は単純明快で、調整する変数が少なく、専門的知識なしで簡単に決定できます。前者は、指定の入力信号に対する開ループ応答波形を組み込み、2個のゲインを手順通りに調整することで設計できます。後者は2個のゲインを順次決定すれば完了します。得られた制御系は,摩擦特性に代表される顕著な非線形特性を持つ機構でも超精密な位置決めを実現します。また後者は他の制御系と組み合わせて利用することも可能です。提示された制御系設計法の有効性は、実験により実証されています。

産業機械の高加速・高速化と精度向上の要求は、ますます高くなっており、高性能な産業機械を開発する際の重要な課題となっています。本研究は、大学研究室の知見を実社会で役立てたいと考える佐藤海二教授と、大学と協力して課題を解決したいというNEOMAXエンジニアリング株式会社の考えが一致し、共同で取り組んで実施されました。当初の目標を達成し、その基本成果を示したのがこの論文です。

論文では、性質が異なる2種類の振動を抑制するように制御系が調整されていますが、さらに多くの周波数の異なる振動が生じる場合や、抑制したい振動の基準が異なる場合、振動の性質が異なる場合などもあります。対応できる場合を増やし、最終的にこれらの問題を総合的に解決する方法を明らかにしたいと考えています。

Researcher Profile

| Name | Kaiji Sato |

|---|---|

| Affiliation | Department of Mechanical Engineering |

| Title | Professor |

| Fields of Research | Precision Mechatronics / Robotics /Control Engineering/ Actuator |

ここでコンテンツ終わりです。