ここからコンテンツです。

Achieving strong structures with carbon fiber reinforced plastics

Strengthening steel using bond-free carbon fiber reinforced plastic laminates By Yukihiro Matsumoto

Associate Professor Yukihiro Matsumoto of the Structural Engineering Laboratory, Department of Architecture and Civil Engineering, Toyohashi University of Technology have developed a new concept for strengthening steel in critical building structures using bond-free carbon fiber reinforced plastic (CFRP) laminates to enhance the buckling performance of structural steel elements. This method does not require steel surface treatment prior to CFRP application because the CFRP is not bonded onto the surface, which contributes to structural strength through its flexural rigidity. The research findings were published in Construction and Building Materials in early 2020.

Following its successful application in the reinforcement of concrete in the civil engineering field, CFRP has now been developed as a means for strengthening steel members instead of conventional steel plates being used. CFRP is preferred because it offers several advantages such as being light weight, and having a high strength-to-weight ratio and excellent fatigue and corrosion resistances. To date, however, research and development on strengthening steel using CFRP has focused primarily on bonding techniques involving CFRP being attached to steel surfaces using an adhesive.

Bonded strengthening presents disadvantages as complex and time-consuming surface treatments are required prior to CFRP installation. Moreover, the bonding strength performance between steel and CFRP, which is the key aspect of this strengthening technique, can also decrease significantly owing to environmental exposure throughout the service life. Replacing this approach with another new bonded-CFRP technique may not provide an appropriate solution because it is unlikely to be cost-effective.

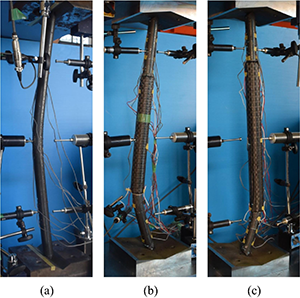

The research team developed its method for strengthening steel using CFRP without bonding it to the steel surface. This method has been shown to delay buckling and increase the compression capacity of steel bars, where the capacity gain is affected by the number of carbon fiber layers used.

"As an alternative to the steel strengthening method using CFRP which is bonded to the steel surface, we developed this unbonded-CFRP method," explained the primary author, Fengky Satria Yoresta. "The major advantages of this method are that it is easier and less time-consuming to implement, especially when it is applied to the existing elements of building structures. No more troublesome steel surface treatments are needed, such as sand blasting, grit blasting, or hand grinding, and this leads to significant cost savings," said the research team leder, Associate Professor Yukihiro Matsumoto.

Associate Professor Yukihiro Matsumoto also saids, "Nearly all previous studies used adhesively-bonded joints to strengthen steel members with CFRP. This method is quite complex because appropriate steel surface treatments are required before the application of the CFRP to obtain an acceptable bond between the CFRP and the steel surface. The surface treatment conditions also affect bonding strengths."

"Moreover, we cannot perfectly estimate the effects of environmental exposure during the service life on the bonding performance between the CFRP and the steel. As such, we sought to improve on conventional methods by developing our own bond-free strengthening method. The unbonded strengthening method is useful, easy to apply, and manageable," he said. "However, our method does not transfer stress smoothly, so an appropriate mechanical model needed to be established. Consequently, we performed mechanical simulations and experiments to demonstrate this," he added.

The findings of their work make the research team members believe that the bond-free CFRP method can be applied not only in civil engineering, but also to other fields such as those in the aerospace, automotive, and marine industries. This promising new method is expected to be adopted to rapidly produce innovative, high-quality products.

Reference

Fengky Satria Yoresta, Ryotaro Maruta, Genki Mieda, Yukihiro Matsumoto (2020). Unbonded CFRP strengthening method for buckling control of steel members. Construction and Building Materials, April 2020, 10.1016/j.conbuildmat.2020.118050.

https://www.sciencedirect.com/science/article/pii/S0950061820300556

炭素繊維強化プラスチックで強靭な構造を実現

炭素繊維強化プラスチック積層板による鋼材の非接着補強法By 松本 幸大

豊橋技術科学大学 建築・都市システム学系、構造工学研究室の松本幸大准教授は、構造用鋼部材の座屈性能を高めるために、炭素繊維強化プラスチック(CFRP)積層板を用いた建築鋼構造部材の非接着による補強手法を開発しました。この手法は、CFRPを鋼材表面に接着しないため、CFRP塗布前の鋼材表面処理が不要で、CFRPの曲げ剛性が構造部材耐力の上昇に寄与します。本研究成果は、2020年始めにConstruction and Building Materials誌に掲載されました。

CFRPは、土木分野でのコンクリート補強への応用に成功し、現在では従来の鋼板に代わって鋼製部材の補強手段として活発に研究開発されています。CFRPは軽量であり、強度重量比が高く、耐疲労性や耐食性に優れているなど、多くの利点があります。しかし、これまでのCFRPを用いた鋼材の強化に関する研究開発は、主にCFRPを接着剤で鋼材表面に接着させる接着技術に焦点が当てられてきました。

接着による補強は、CFRPを取り付ける前に複雑で時間のかかる表面処理が必要となる欠点があります。さらに、その補強技術の性能に重要な鋼材とCFRPの接着強度は、耐用年数を通して自然環境にさらされることにより低下する可能性があります。この方法を別の新しい補強CFRP技術に置き換えることは、費用対効果が低く、適切な解決策にならない可能性があります。

本研究チームは、鋼材表面にCFRPを接着することなく鋼材を補強する方法を開発しました。この方法により、座屈を遅延させることで鋼部材の圧縮能力を向上させることを示しました。

「鋼表面に接着するCFRPを用いた鋼材の補強法に代わる方法として、この非接着CFRP法を開発しました」と論文の筆頭著者であるFengky Satria Yorestaは説明しています。「この方法の大きな利点は、特に建築構造物の既存要素に適用する場合、実装が簡単で時間がかからないことです。サンドブラストやグリットブラスト、手研ぎなどの面倒な鋼材表面処理が不要になり、大幅なコスト削減につながります」と研究チームリーダーの松本幸大准教授は述べています。

また、松本幸大准教授は、「これまでのほとんどすべての研究は、鋼製部材をCFRPで補強するために接着剤で接合していました。その方法は、CFRPと鋼材表面との間の必要な接着強度を得るために、適切な鋼材表面処理を行う必要があるため、非常に複雑になります。また、表面処理条件も接着強度に影響してしまいます。」と述べています。

「さらに、耐用年数中の環境暴露がCFRPと鋼材との接着性能に与える影響を、完全に予測することはできません。そこで、独自の非接着補強工法を開発することで、従来工法の改善を図りました。非接着補強法は実応用・管理も容易です。しかし、この方法では応力がスムーズに伝達されないため、適切な力学モデルを確立する必要がありました。そのため、解析シミュレーションと実験を行い、それを確立・実証しました」と付け加えています。

この研究成果は非接着補強法が土木分野だけでなく、航空宇宙、自動車、船舶などの他分野への応用も可能であると、研究地チームのメンバーは考えています。この有望な新工法は、革新的で高品質な製品を迅速に生産するために採用されることが期待されています。

Researcher Profile

| Name | Yukihiro Matsumoto |

|---|---|

| Affiliation | Department of Architecture and Civil Engineering |

| Title | Associate Professor |

| Fields of Research | Structural Engineering |

ここでコンテンツ終わりです。