ここからコンテンツです。

Development of a new thermoelectric material for a sustainable society

The first synthesis of bulk CaMgSi with thermoelectric properties.By Yoshikazu Todaka

Yoshikazu Todaka and his colleagues, in cooperation with researchers at the Nagoya Institute of Technology, have developed a new thermoelectric material, Calcium-Magnesium-Silicide (CaMgSi), which consists of non-toxic, cheap, and lightweight elements.

These findings could contribute to the development of green energy technology.

Thermoelectric materials, which can directly convert thermal energy into electrical energy (Seebeck effect), can be effectively used for the development of a clean and environmentally compatible power-generation technology.

However, these materials are not commonly used for practical applications as they mostly include toxic and/or expensive elements.

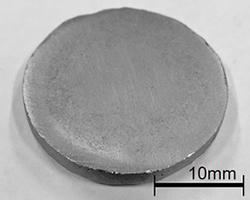

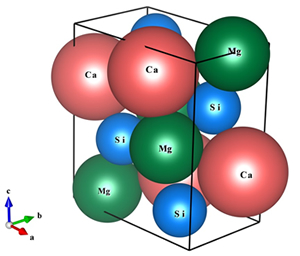

Recently, Professor Yoshikazu Todaka and his research group from Toyohashi University of Technology’s Materials Function Control Laboratory and the Nagoya Institute of Technology have successfully synthesized a new thermoelectric material, CaMgSi, which is an intermetallic compound. The key to this development was the synthesis procedure; bulk CaMgSi intermetallic compound was synthesized by combining mechanical ball-milling (MM) and pulse current sintering (PCS) processes.

"Significant thermoelectric properties in the intermetallic compound, CaMgSi, have been predicted by both theoretical and experimental studies”, explain the researchers of this work, Nobufumi Miyazaki and Nozomu Adachi. " However, the biggest issue in front of us was the synthesis of thermoelectric CaMgSi of optimal size ", they continued. In general, alloys are produced by mixing the constituent elements in their molten forms. However, Mg vapors when the temperature is raised up to the melting temperature of Si; Ca, Mg, and Si can no longer exist in their liquid states.

Yoshikazu Todaka says "To overcome the aforementioned problem, we chose the mechanical ball milling process to mix the elements homogeneously, without melting, and then a chemical reaction between Ca, Mg, and Si was induced using the pulse current sintering process".

Consequently, it became possible to synthesize the intermetallic compound, CaMgSi, on a sufficient scale. The thermoelectric property of the synthesized CaMgSi exhibited a performance comparable to that of the previously developed Mg-based thermoelectric materials. It is expected that the slight change in the composition of CaMgSi and the addition of a fourth element to CaMgSi will further enhance its thermoelectric properties. Interestingly, they found that the novel thermoelectric material can exhibit both n- and p-type conductivity. Such a property is very significant for the application of such material in power-generation modules.

The new thermoelectric material synthesized in this study is composed of lightweight elements, and has a low density of 2.2 g/cm3. Therefore, one of the possible applications of the material is in automobiles to utilize waste heat emitted from engines. These findings could contribute to the development of green energy technology.

This study was supported by Iketani Science and Technology Foundation (Grant No. 0271039-A). A part of this study was performed at the BL02B2 beamline of the SPring-8 synchrotron radiation facility with the approval of the Japan Synchrotron Radiation Research Institute (Proposal No. 2014B1237).

Reference

Nobufumi Miyazaki, Nozomu Adachi, Yoshikazu Todaka, Hidetoshi Miyazaki, and Yoichi Nishino (2017). Thermoelectric property of bulk CaMgSi intermetallic compounds, Journal of Alloys and Compounds, 691, 914-918. 10.1016/j.jallcom.2016.08.227

持続可能な社会に向けた新熱電材料の開発

新規熱電材料CaMgSiの初合成豊橋技術科学大学の戸高義一教授と名古屋工業大学の研究チームは、無害・安価・軽量な元素のみで構成された新規熱電材料CaMgSiの開発に成功しました。この発見により、グリーンエネルギー技術の発展が加速されると予想されます。

「熱電材料」はゼーベック効果により熱エネルギーを電気エネルギーに直接変換可能なクリーンで環境適応性が高い発電材料です。しかし、ほとんどの熱電材料が有害元素や高価な元素を含むため、応用例は限られています。

そのような現状の中で、研究チームは「CaMgSi金属間化合物」という新規な熱電材料の開発に成功しました。この新規熱電材料CaMgSiの開発のキーとなる技術に、材料作製技術があります。本研究では、メカニカルボールミリング法とパルス電流焼結法を組み合わせた作製技術が採用されています。

CaMgSiに熱電特性があろうことは、理論・実験の両研究からも予想は出来ていましたが、この研究の一番の問題は如何に単体のCaMgSiを熱電材料に足る大きさで作製するかでした。金属間化合物のような合金の作製は、それぞれの元素を溶かして液体状態で混ぜ合わせる溶製法を用いるのが一般的です。しかしCaMgSiでは、温度をSiの融点がMgの沸点を超えており、3元素の液体状態を同時に得ることが出来ません。

この問題を克服するために、メカニカルボールミリングにより各元素を溶解させること無く機械的に混合した後に、パルス電流焼結により化合物形成反応を促すことでCaMgSiを作製する方法を編み出しました。

その結果、充分な大きさのCaMgSi金属間化合物の作製に成功しました。作製したCaMgSiは過去に開発されたMg系熱電材料に匹敵する特性を示しました。今後の研究で、CaMgSiの組成を少し変更することや第4元素を添加したCaMgSiを作製することによって、より優れた熱電特性を発現する可能性があります。また、p型、n型の導電性を有するよう容易に制御できることが明らかになりました。この特性は、実際のモジュールへ応用する際に重要となります。

CaMgSiは、軽量な元素のみで構成されていることから、その密度は2.2g/cm3と小さいことも特徴です。従って、エンジン部等からの排熱を再利用する発電デバイスを自動車に搭載することが将来の応用先として考えられます。

本研究は、公益財団法人 池谷科学技術振興財団(Grant No. 0271039-A)の助成を受けて行われました。また、本研究の一部はSPring-8, BL02B2(課題番号2014B1237)にて実施されました。

Researcher Profile

| Name | Yoshikazu Todaka |

|---|---|

| Affiliation | Department of Mechanical Engineering |

| Title | Professor |

| Fields of Research | Physical Metallurgy |

ここでコンテンツ終わりです。