ここからコンテンツです。

Development of three channel SQUIDs contaminant detector for food inspection

By Saburo Tanaka

In terms of food safety, the mixture of contaminants in food is a serious problem for not only consumers but also manufacturers. In general, the target size of a metallic contaminant to be removed is 0.5 mm. However, it is a difficult task for manufacturers to achieve this target, because of the present lower system sensitivity. Therefore, we developed a food contaminant detection system based on high-Tc RF superconducting quantum interference devices (SQUIDs), which are highly sensitive magnetic sensors. This study aims to improve the signal to noise ratio (SNR) of the system and detect a 0.5 mm diameter steel ball. Using a real time digital signal processing technique along with analog band-pass filters, we improved the SNR of the system. Owing to the improved SNR, a steel ball with a diameter as small as 0.3 mm, with a stand-off distance of 117 mm was successfully detected. These results suggest that the proposed system is a promising candidate for the detection of metallic contaminants in food products.

The mixture of metallic contaminants into food is a serious problem not only for consumers but also manufacturers. To ensure food safety, the finding of small metallic contaminants is important. A piece of metal may, for example, come loose from a machine used in the processing of food which may consequently cause metallic contamination. Thus, finding small metallic contaminants is important for food safety. Presently, food manufacturers are installing inspection systems such as eddy current detectors and X-ray imaging. In particular, the eddy current metal detector is widely used in food factories. However, its sensitivity (threshold level) is unstable and is highly influenced by the conductivity of the material being detected. X-ray imaging is a useful technique and is gaining popularity in food factories and in other various industries. However, the lower detection limit for practical X-ray usage is in the order of 1 mm. Moreover, X-ray radiation sometimes causes ionization of the food, which may often change the taste of the food.

We are proposing a detection system using SQUID magnetic sensors to circumvent the difficulties outlined above [1-4]. We have developed a detection system that inspects food packages with a height of 100 mm, which is the size required for practical food inspection. Since the signal is reduced if the distance between the sensor and the target (stand-off distance) becomes large, improvement of the signal to noise ratio (SNR) for a practical system is required. Therefore, a program of a real time digital filter was developed and applied to the system. The target size of the metallic contaminant in food is diameter of φ0.5mm.

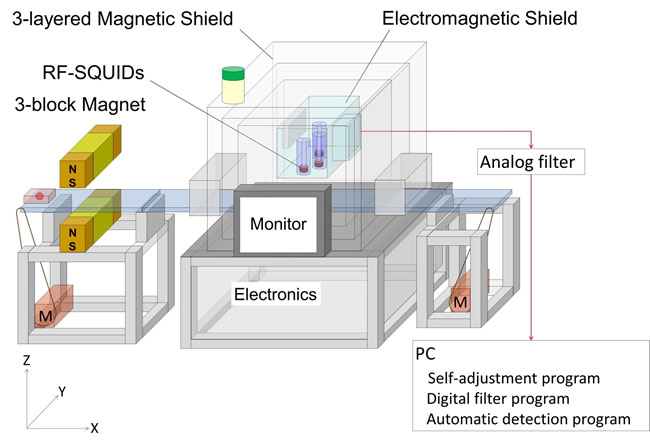

The system consists of a permanent magnet, a conveyor belt, a mu-metal magnetic shield box, an aluminum electro-magnetic shield box and three High-Tc RF SQUID magnetometers. The controlling and data processing software used was developed exclusively for this system. A block diagram of the detection system is shown in Fig.1. The detection technique is based on recording the remnant magnetic field of a magnetic contaminant using a SQUID magnetometer. The packaged food is conveyed on a conveyor belt and passes the gate of the magnet. The SQUID sensor senses the remnant magnetic field of a metal contaminant in the food. The SQUID and its driving electronics were manufactured by Juelicher SQUID GmbH (JSQ). The noise of each RF SQUID magnetometer in the system is 300-600fT/Hz1/2 at 10Hz, and 70-170fT/Hz1/2 at the noise floor (>1kHz). The signals of the SQUIDs output were filtered in an analog high pass filter (-6dB/oct, fc=0.4Hz) and a low pass filter (-24db/oct, fc= 11Hz), but SNR was not enough to detect the signal of a steel ball (SUJ-2) φ0.5mm. Therefore we considered the introduction of a real-time moving average digital filter in addition to the analog filters. A program (C++) for the digital filter was developed and evaluated using the system. The experimental conditions are as follows; conveyer speed: 20 m/minute, Stand-off (distance from SQUID to the test sample): 117 mm, test samples: steel ball φ0.3-0.8mm, sampling rate: 20-1000 Hz, and number of averaging points: 2-500.

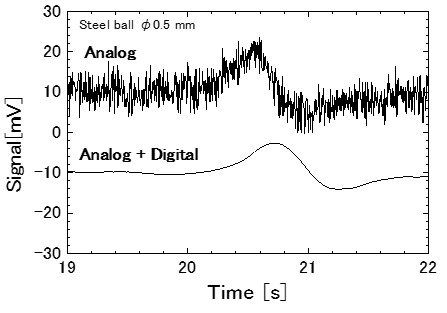

The time trace for the test sample φ0.5 mm is shown in Fig. 2. Trace (a) was obtained before digital processing (analog HPF and LPF are applied), and trace (b) was obtained after digital processing. Trace (b) is clear; the random noise is 92 % reduced but the peak-to-peak value is 22 % smaller than that before digital processing. As a result, the SNR is improved approximately 10 times.

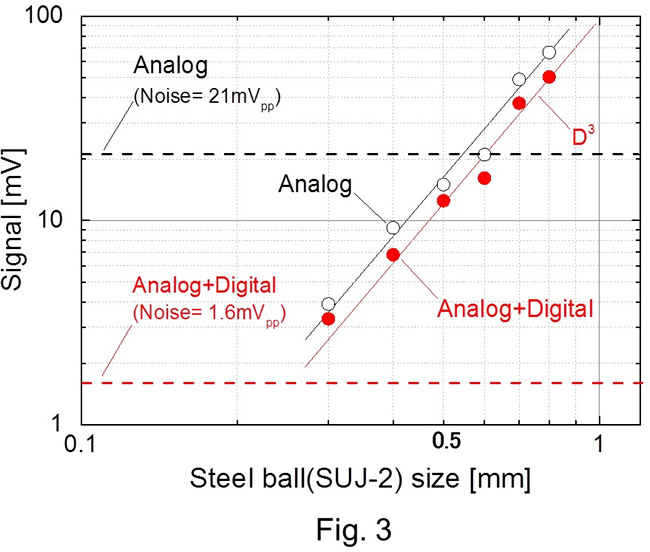

Fig.3 shows the dependence of the SQUID output peak signal on the sample diameter. The signals scaled well with the cube of the diameter, which suggests that the signal was proportional to the volume of the sample. By applying the digital filter, the SNR for a steel ball of φ0.4 mm is 4.2, which is more than the threshold level of SNR=3. Therefore, the target of our project, which is SNR>3 for a steel ball of φ0.5 mm with distance of 100mm, has been accomplished by the application of the digital filtering technique.

Finally, these results suggest that the system is a promising tool for the detection of metallic contaminants in practical applications.

Patents

- 特願2012-19175 「微小磁性金属異物の検査装置」

- 特願2013-165576 「磁性金属異物を検出するための装置」

- 特願2013-175030 「磁性金属異物を検出するための装置と方法」

- 特願2015-024016 「磁性金属異物の検出方法及び検出装置」

- 特願2015-024017 「磁性金属異物の検査装置と検出方法」

Reference

S. Tanaka, M. Natsume, M. Uchida, N. Hotta, T. Matsuda, Z. Aspanut, et al., "Measurement of a metallic contaminant in food by high-Tc SQUID," Supercond. Sci. Technol., vol. 17, pp. 620-623, 2004.

M. Bick, P. Sullivan, D. L. Tilbrook, J. Du, B. Thorn, R. Binks, et al., "A SQUID-based metal detector: comparison to coil and X-ray systems," Supercond. Sci. Technol., vol. 18, pp. 346-351, 2005.

H. J. Krause, G. I. Panaitov, N. Wolter, D. Lomparski, W. Zander, Y. Zhang, et al., "Detection of Magnetic Contaminations in Industrial Products Using HTS SQUIDs," IEEE Trans. on Appl. Supercond., vol. 15, pp. 729-732, 2005.

S. Tanaka, Y. Kitamura, Y. Uchida, Y. Hatsukade, T. Ohtani, and S. Suzuki, "Development of Metallic Contaminant Detection System using Eight-Channel High-Tc SQUIDs," IEEE Trans. Appl. Supercond., p. 1600404, 2013.

超伝導量子干渉素子(SQUIDs)を利用した異物検査技術

食品の安全性確保の見地から、食品への異物混入は消費者のみならず製造業者にとっても非常に深刻な課題となっています。一般に、除去対象となる混入金属異物の大きさは0.5mm程度ですが、汎用検査システムの測定感度等に制限があり、製造業者にとってこの目標を達成することは非常に困難なものとなっています。このような背景の下、我々は高感度磁気センサであるRF超電導量子干渉素子(SQUID)を用いた食品中異物検査装置を開発しました。アナログバンドバスフィルタと実時間ディジタル信号処理の適用により装置のS/N比を向上することで、スタンドオフ距離117mmの条件下にて0.3 mm径の鋼球を検出することに成功しました。本成果は、開発システムが食料製造品中の混入金属異物検出に極めて有望であることを示すものです。

金属異物は主に食品製造中に混入することが多く、その検出技術の開発は食の安全を確保する観点で、非常に重要です。食品製造業者の工場には、渦電流検出装置やX線イメージング装置が導入されています。しかしながら、前者においては、混入金属の電気伝導率に検出感度が大きく左右される課題があります。また、後者においては、異物サイズの検出限界は1 mm程度であることに加え、X線照射による食品の味等への悪影響も懸念されています。

これらの問題の克服に向けて、私たちはSQUID磁気センサを用いた金属異物検査システムを提案し、実際の食品検査で要求される高さ100mmの食品パックに適用可能な検査システムを開発しました。検出すべき信号の強度はセンサと検出対象物の距離(スタンドオフ距離)と共に減少するため、実際の検出システムにおいては、S/N比(SNR)の向上が非常に重要な技術課題となります。実時間ディジタルフィルタの活用により、0.5mm径の鋼球を検出することを開発目標としました。

Fig 1に示す通り、検査システムは永久磁石、食品移動用コンベヤー、高透磁率合金製磁気シールドボックス、アルミ製電磁シールドボックス、3チャンネル高温RF-SQUID磁気センサから構成されます。また、本装置用の制御及びデータ処理ソフトウェアを開発しました。パッケージングされた食品はベルトコンベヤー上を移動し、永久磁石のゲートを通過する構成となっています。SQUID磁気センサは食品中の金属異物の残留磁化信号を検出します。SQUIDセンサの出力信号はアナログハイパスフィルタ(-6dB/oct, fc = 0.4Hz)およびローパスフィルタ(-24dB/oct, fc=11Hz)でフィルタリングされますが、S/N比は0.5mm径の鋼球を検出するには不十分でした。この問題の克服に向けて、私たちは、上記のアナログフィルタに加え実時間ディジタルフィルタの導入を提案し、制御プログラムの開発に取り組みました。検出試験の条件は、コンベヤー移動速度:20 m/min、スタンドオフ距離:117 mm、鋼球サンプル径:0.3-0.8 mm、サンプリングレート:20-1000 Hz、およびアベレージング数:2-500に設定しました。

直径0.5mmの鋼球を用いた測定結果(Fig 2)よりディジタル信号処理の適用によってノイズが大きく低減されており、S/N比は約10倍向上していることを確認しました。更に、SQUIDセンサの検出信号の鋼球サンプル径依存性(Fig 3)より、検出信号は鋼球系の3乗にスケーリングしていることが確認され、検出信号強度は鋼球サンプルの体積に比例することが示唆されました。ディジタルフィルタの適用によりSNRを大きく低減することができ、結果として開発目標としていた0.5mm径の鋼球を、スタンドオフ距離100mmの条件下にて達成することに成功しました。本結果は、開発した検査システムが、実用的な金属異物検査に向けた有望なツールであることを示唆するものと言えます。

Researcher Profile

| Name | Saburo Tanaka |

|---|---|

| Affiliation | Department of Environmental and Life Sciences |

| Title | Professor |

| Fields of Research | Superconducting Electonics / Bio Sensing Application / Sensor Technology/ Contaminant detection/ Nondestructive Evaluation |

ここでコンテンツ終わりです。