Research highlights

Development of the world’s strongest magnesium alloy

There is strong demand for the improvement of the mechanical properties (particularly the strength) of magnesium (Mg) alloys to meet the growing industrial applications of structural materials.

Hiromi Miura and colleagues* applied severe plastic deformation, that is, multi-directional forging (MDF), to commercial brittle Mg alloys by controlling pass strains and severe plastic deformation was realized without any cracking up to cumulative strain of 2.0.

The coarse initial grains were gradually subdivided into ultrafine grains by mechanical twinning. The initial coarse twins were further subdivided by higher order mechanical twins. The average grain size achieved at a cumulative strain of 2.0 was as fine as 0.3 ㎛.

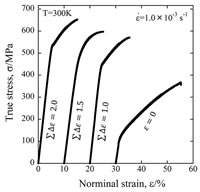

The Mg alloy produced by MDF showed an excellent balance of mechanical properties of 530 MPa yield stress, 650 MPa ultimate tensile strength, and 9% plastic strain to fracture (Fig. 1). This was the world strongest Mg alloy ever produced.

The ultrafine grain structure and suppression of texture resulted in the extraordinarily high strength without spoiling ductility.

The researchers are now conducting experiment to produce large sizes samples of the MDFed Mg alloys.

- Reference:

- Authors: H. Miura and W. Nakamura

- Title: Microstructure and Mechanical Properties of Mg-8Al Alloy Fabricated by Room-Temperature Multi-Directional Forging

- Journal: Philosophical Magazine Letters. Vol.93, pp.601-607, 2013.

- Digital Object Identifier (DOI): 10.1080/09500839.2013.827800

- Affiliation: Department of Mechanical Engineering, Toyohashi University of Technology.

*This research was conducted at the University of Electro-Communications, Tokyo.

Hiromi Miura

Fig.1: True stress vs. true strain curves obtained by tensile

Enlarge Image