Feature

Growing plants in factories

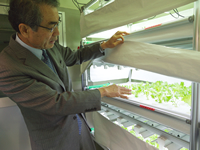

Project Professor Masahiko Saigusa and his team of researchers at Toyohashi Tech’s Research Center for Agrotechnology and Biotechnology are investigating ways of growing vegetables more efficiently using intelligent greenhouses and plant factories.

“When you grow vegetables out in a field, you are dependent on the whims of the climate,” says Saigusa. “But in an intelligent greenhouse or plant factory, you control the climate by controlling crucial elements such as the quality or amount of light, temperature, humidity and nutritional availability.”

Light in these facilities may be a combination of sunlight and artificial light, or completely artificial light; temperature is controlled using air conditioning; while liquid nutritional intake is carefully monitored. “This makes the environment much more stable,” explains Saigusa, “and is the reason why we can enjoy fruits and vegetables like tomatoes, strawberries and leafy greens all year round that are free of or low in pesticides”

The Center is also researching how to decrease the phosphate content in soil and nitrate in plants. In field cultivation, to get several crop yields a year, the soil requires fertilization for each planting. This may lead to an overdose of phosphate, which can deplete the mineral content of plants such as iron and manganese, while nitrate, when over-consumed, is considered a health hazard by some countries, including the European Community. By developing new kinds of iron minerals and analyzing and changing soil content, the Toyohashi Tech researchers have been able to reduce iron deficiencies and have found ways to greatly reduce the amount of nitrate used for fertilization.

Another area of research is solution culture and hydroponic farming: growing plants using water and mineral nutrients but without soil. One Toyohashi Tech intelligent green house contains rows of tomato vines fed with liquid fertilizer and growing from containers of coco peat, the by-product of coconut husks that is used for bedding the vines. “The entire system is remotely controlled and managed by computer and wireless sensors,” says Saigusa. “This makes it efficient and cost effective.”

In addition to research, the Center has recently begun a program backed by the Japanese government for training plant factory managers. It consists of five months of classroom learning, then 12 months of e-learning and practical training. “Having the students first come together in a classroom helps create friendships and encourages the students to communicate with each other later during the e-learning period,” says Saigusa. “Typically, you see around 30 percent of students graduate from this type of program, but by using our approach, we achieved a ratio of 90 percent in the first year.”

Project Professor Masahiko Saigusa

Enlarge Image

Vegetables under illumination

Enlarge Image

Project Professor Masahiko Saigusa opening a light illuminated plant growth bed

Enlarge Image