ここからコンテンツです。

Aiming to improve joint connection technologies for light-weight and high-strength structures

New design method for fiber reinforced polymer buildingsYukihiro Matsumoto

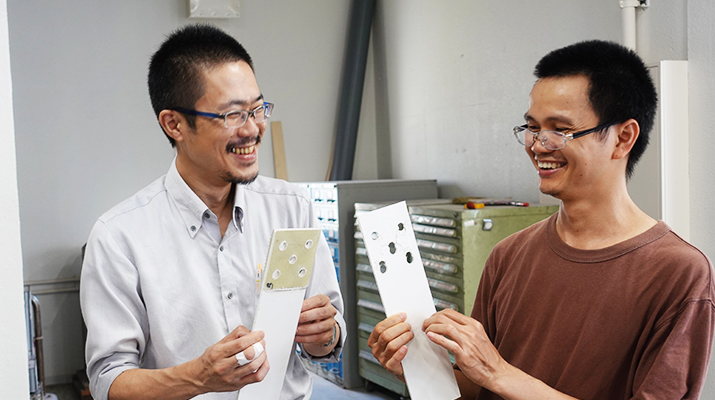

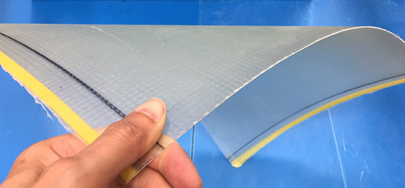

A research team (led by Professor Yukihiro Matsumoto) formed as a collaborative project between Toyohashi University of Technology’s Department of Architecture and Civil Engineering of and Electronics-Inspired Interdisciplinary Research Institute (EIIRIS) proposed and demonstrated a method for improving the dynamic behavior of bolted connections by using Glass Fiber Reinforced Polymer (GFRP) materials. As pultruded GFRP materials used in construction applications have reinforced fiber directions aligned along the axis of the member axis, bolted connections are fragile and at a disadvantage in design. The research team demonstrated that a noticeable increase in bearing strength can be realized by pasting a thin GFRP plate to the bolted connection. The plate uses a multiaxial base material molded by vacuum-assisted resin transfer molding which enables high-quality molding,. The research team also demonstrated that this method could improve the fragile fracture behavior of the joint connections. The results of this study will enable the design of safer, more secure, and lighter building structures with longer lifespans.

Because of its light weight and high strength, applications for Fiber Reinforced Polymer (FRP) have been increasing, such as its use in the repair and reinforcement of existing buildings, pedestrian bridges, and floodgates. It is expected that FRP material will be used in emergency repairs of structures and the structures of new buildings in the future. The pultrusion method, one of the methods for producing FRP members, can produce long members with ultra-high productivity. It is a commonly used molding method for FRP architectural members. However, because the pultrusion method generally places many reinforced fibers, which ensure the strength and stiffness of FRP materials, in the direction of pultrusion (along the longitudinal axis of the member), it is known to show local damage and brittle fractures around bolt holes when connections are made using bolts, etc. Therefore, care needs to be taken regarding this fracture behavior.

Therefore, the research team has performed research to minimize the increase in weight and production costs and to improve the dynamic behavior of bolted connections. They attempted to achieve this by using vacuum-assisted resin transfer molding, which is used to make parts of ships and blades of wind turbines made of FRP, and by pasting a GFRP plate that is several millimeters thick and has multiple fiber directions.

By reinforcing the necessary areas with only the necessary amount of GFRP, they demonstrated in their experiments that the connection strength of fiber reinforced polymer can be increased significantly without losing the productivity or light-weight properties of FRP. In addition, based on the experimental results and existing design formulas, the research team also proposed design formulas for when their proposed connection-reinforcing method is used and successfully provided data that can be applied in design.

The research team leader, Professor Yukihiro Matsumoto, said; "As the name suggests, fiber reinforced polymer is a material that requires the good use of fibers. We have reached this idea by observing the fracture behaviors of connections through previous experiments and collecting information on various FRP molding methods. Though it is simple, what we needed was only the pasting of a thin plate to the connection. I am surprised that good effects were observed by carefully considering fiber direction. I think the useful and general-purpose results were obtained due to the enthusiasm of the Ph.D. students in the determination of experimental variables and the development of an experiment plan."

Going forward, the research team will demonstrate the effectiveness of their proposed connection method through connection experiments assuming construction structures as well as experiments and analyses of full-scale specimens and will promote the development of these reinforced connections, aiming for their applications as a reinforcement method for existing FRP structures.

Reference

Phan Viet Nhut, Quang Duc Tran, Yukihiro Matsumoto: Pin-bearing connection strength of single-bolted pultruded GFRP profiles strengthened by glass fiber sheet, Polymer Composites, 2022.6.

https://doi.org/10.1002/pc.26774

Quang Duc Tran, Nhut Phan Viet, Yukihiro Matsumoto: Multi-Bolted Connection for Pultruded Glass Fiber Reinforced Polymer's Structure: A Study on Strengthening by Multiaxial Glass Fiber Sheets, Polymers, Volume 14, Issue 8, 1561, 2022.4.

https://doi.org/10.3390/polym14081561

軽量高強度構造物の接合技術の改善に向けて

繊維強化プラスチック建設物の新しい設計法松本 幸大

豊橋技術科学大学 建築・都市システム学系とエレクトロニクス先端融合研究所の研究チーム(松本 幸大教授)は、ガラス繊維強化プラスチック(GFRP)材料を用いたボルト接合部の力学挙動の改善法を提案・実証しました。建設用途で用いられる引抜成形GFRP材は強化繊維方向が部材軸方向に揃っているため、ボルト接合部が脆弱であり、設計面で不利となっていました。そこに、高い品質で成形が可能な真空樹脂含浸成形(Vacuum assisted Resin Transfer Molding)によって成形した多軸基材を用いた薄肉GFRP板材を貼付することで、大幅な耐力上昇が実現できることを示しました。加えて、接合部の脆性的な破壊挙動も改善できることを示し、本研究成果により、より安全安心で長寿命・軽量な建設構造物の設計が可能となります。

繊維強化プラスチック(FRP)は軽量・高強度で耐力性も有する材料であることから、近年、既存建設物の補修・補強のための材料や、歩道橋、水門などに応用が広がっている材料で、今後も応急復旧用の構造物や設備構造への応用が期待されています。FRP部材を製造する手法の一つである引抜成形法は、長尺の部材を極めて高い生産性で製造できる成形法であり、建設部材向けのFRP成形法として広く使われています。しかし、引抜成形法では一般的にFRP材の強度・剛性を担保する強化繊維が引抜方向(部材の軸方向)に多く配置されることから、ボルトなどで接合した場合、ボルト孔周辺での局所的なダメージや、脆性的な破壊を示すことが知られており、設計の際は注意を要する破壊挙動となっていました。

そこで、研究チームは、FRP製の船舶や風力発電ブレードなどに用いられる真空樹脂含浸成形(Vacuum assisted Resin Transfer Molding)を応用し、接合部周辺に板厚数ミリメートル程度の複数の繊維方向を有するGFRPを貼付することで、重量増加や製造コストの増加を最小限に、接合部力学挙動の改善を行う研究を進めてきました。

必要な所に必要な分だけ補強することで、生産性や軽量性を損なわず、繊維強化プラスチックの接合強度を大幅に上昇できることを実験により示しました。また、実験結果と既存の設計式を元として、研究チームが提案する接合部補強法を適用した際の設計式も提案し、設計に応用可能なデータを提供することが出来ました。

研究チームのリーダーである松本 幸大教授は「繊維強化プラスチックは文字通り繊維を上手く使ってあげることが必要な材料です。これまで実験を通して接合部の破壊形態を観察すること、また様々なFRPの成形法の情報収集を行うことで、このアイデアに至りました。薄い板を貼るだけとは単純ですが、繊維方向を上手く考えることで大きな効果がでたことに驚いています。博士後期課程学生が大変熱心に実験変数の決定と実験計画を立てくれたことで、有用で汎用性のある成果に結びついたと考えています。」と語っています。

研究チームは、今後、実際の建設構造物を想定した接合部実験や実大相当の実験・解析を通して、提案する接合法の有効性を示していくとともに、既存のFRP構造物の補強法としても応用できないか、発展を進めていきたいと考えています。

Researcher Profile

| Name | Yukihiro Matsumoto |

|---|---|

| Affiliation | Electronics-Inspired Interdisciplinary Research Institute(EIIRIS) |

| Title | Professor |

| Fields of Research | Structural Engineering |

| Graduated KOSEN | National Institute of Technology, Yonago College |

ここでコンテンツ終わりです。