ここからコンテンツです。

Visualizing the biological information of plants to benefit the future of agriculture

Kotaro Takayama

Agriculture in Japan is presently undergoing a period of change. Over the last five years, elderly agricultural workers are leaving the industry at an accelerated pace. Going forward, the farming population is predicted to decline rapidly. On the other hand, as middle-aged people focus on their health, demand for fresh vegetables is growing, and ensuring their stable supply has become an urgent issue. This has led to attention on indoor farming and intelligent greenhouses that efficiently and stably produce vegetables. To meet this challenge, Professor Kotaro Takayama is working on developing solar-powered indoor farms which practise smart agriculture by monitoring the biological information of plants and analyzing the collected data. With such systems already in place, Professor Takayama's work is now gaining recognition.

Interview and report by Madoka Tainaka

Establishing "strong agriculture" as a business

In any era, a stable supply of food is an essential issue. With farms in Japan largely family operated, Professor Takayama worries about their ability to continue operating in the future. In addition, the population of farmers continues to rapidly decline, and consumer habits will significantly change over the next ten years. In order to respond to both of these issues, Professor Takayama states that it is essential to create a new agricultural production system that can provide a stable supply of fresh vegetables and other goods.

According to Professor Takayama, "The best option is indoor farming and/or intelligent greenh ouses. If you look at the situation of about ten years ago, hand-grown vegetables from local farmers were significantly more popular than indoor-grown varieties, but today it is now possible to provide a stable supply of greenhouse-grown vegetables offering 100% traceability. Greenhouse-grown vegetables are now increasingly entering the mainstream for consumers due to their proven quality, safety and security. With middle-aged people focusing on their health, and the demand for fresh vegetables having grown by around 150% to 200% over the past ten years, I believe that, moving forward, reliance on large-scale indoor farms will gradually increase . On the other hand, operating such facilities requires adequate financing, which means the farms will need to establish proper business models. To achieve that, managing production will be essential. Up to now, this industry has relied mainly on the intuition and experiences of experts, but there was essentially no scientific approach," says Professor Takayama.

Knowledge about environmental controls for indoor farms first developed approximately 20 years ago, and automated computer controls are already being implemented across the world. However, testing has not been sufficient. To address this, Professor Takayama created an optimal production system to monitor plant growth and regulate the environment using extremely low-cost methods.

"A scientific approach is sure to improve productivity," he says. "However, even if yields increase by 400% or 500% compared to a normal greenhouse, it is pointless without a business model. We need to look at the balance between cost and revenue while providing optimal production. To do this, we first need to measure conditions, analyze the resulting data, and determine optimal production. If we can do that, I believe we can realize a strong agricultural industry that can compete in the marketplace," says Takayama.

Measuring and diagnosing plant photosynthesis, controlling the cultivation environment

Addressing this, Professor Takayama has adopted image-based measurements and analyses to understand plant growth conditions. He goes on to explains the background behind his methods.

"CCD cameras that would have cost 1,000,000 yen 10 years ago have become cheaper, and cameras with the same functions are now equipped on smartphones. It is now even possible to analyze images with smartphones. Due to this, image analysis technology can now be brought on site to the farm," he says.

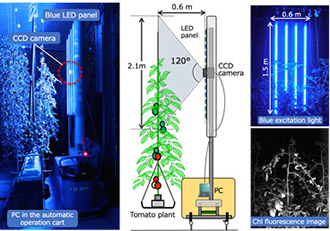

Particularly revolutionary is his research that uses images to capture the plant's photosynthetic activity. In a world first, Takayama developed a robot that can automatically measure photosynthesis in indoor farms. In 2017, Iseki & Co., Ltd. began selling the robot as a diagnostic device for plant cultivation. Indoor farms are broadly divided into artificially lit facilities that use LEDs and other artificial light sources, and solar-powered varieties. Professor Takayama focuses on the latter.

"The robot automatically moves throughout the solar-powered indoor farm at night and measures fluorescent imagery of tomato chlorophyll (Chl)," he explains. "Chlorophyll absorbs light energy, and the chlorophyll fluorescence is a portion of leftover energy that was not used in photosynthesis. It is discharged as red light.

To measure this, the leaves of the tomatoes are illuminated at night using a blue LED excitation light. Then, the robot stimulates the photosynthesis reaction system artificially and the change in the intensity of the chlorophyll fluorescence is measured. The process by which the chlorophyll fluorescence intensity changes with time is called an ‘induction phenomenon.' In 1987, my instructor, Kenji Omasa, Professor Emeritus of the University of Tokyo, became the first person in the world to take image measurements of this process. Changes in fluorescence intensity show the plant's photosynthetic capabilities and stress impacts, so it is helpful in understanding plant conditions."

Upon actually using the robot to measure a 170- by 76-meter greenhouse growing 30,000 tomato plants, it became clear that photosynthesis activity varied by location. Visualizing the analysis results through a heat map makes it possible to improve the state of growth by controlling various environmental conditions such as water volume and temperature.

Using a variety of new technologies to bring about innovations in agriculture

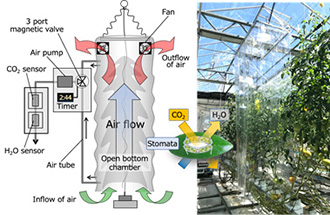

Professor Takayama is also working on a real-time monitoring system to measure photosynthesis. With this system, the cultivated plants are wrapped in tubular, transparent vinyl bags, and the rate of photosynthesis and transpiration is examined by measuring the concentration difference of H2O and CO2 in air flowing in from below the tube, and in the air ejected from a fan above. The low-priced sensor's ability to precisely measure photosynthesis and transpiration has garnered attention, and in 2019, the system went on sale as a joint collaboration between Kyowa Co., Ltd. Division of Hyponica and Plant Data, a venture launched by Toyohashi University of Technology. The system is getting lots of attention, with inquiries even coming from countries with advanced agricultural industries, such as Holland.

"Though increasing CO2 concentration encourages photosynthesis, injecting CO2 is not necessary if there is already sufficient photosynthesis occurring. This reduces cost." explains Professor Takayama.

In addition, a cheaper lightweight hanging robot that can be used in conventional small and mid-size greenhouses to measure plant biology imagery information is also being offered. In addition to measuring chlorophyll fluorescence imagery, moving the camera up and down makes it possible to capture color images of the entire plant and precise details. Using deep learning to analyze the acquired images makes it possible to automatically detect changes in growth along with flowering and fruit bearing conditions. This is helpful in predicting harvest time and yield. Work is also underway to develop a visual user interface that will make this information intuitive to understand.

"Deep learning is an incredibly groundbreaking technology. You can quickly analyze and develop growth models that would have previously taken a significant amount of time. Gathering large volumes of data from daily measurements makes it possible to further increase precision. Deep learning-equipped AI makes it possible to dramatically change conventional agriculture." says Takayama.

In addition, research and development is advancing to measure plant stress conditions by utilizing super-compact odor sensors equipped with ultra-sensitive silicon CMOS ion imaging sensors developed at the university by Professor Kazuaki Sawada.

"In fact, neighboring plants communicate with smell, and diagnosing these odors shows us the health of the plant. Though I learned this when studying abroad in Holland in 2007, at the time I could have never imagined that we would be able to develop small, low-cost sensors. We can use these odor sensors as alarms to show us when there is insufficient water or too much pesticide. Furthermore, we expect these simple sensors will be able to be used at production sites," says Takayama.

With abnormal weather patterns and disasters common in today's world, more and more people are looking for a reliably priced supply of vegetables that can be consumed with peace of mind. Professor Takayama's accomplishments put him at the forefront of such future innovations in agriculture.

Reporter's Note

Fond of biology and physics from a young age, upon arriving at university, Professor Takayama studied agricultural machinery and agricultural civil engineering. His field of study focused mainly on the durability of agricultural machinery, which was not a popular field at the time. However, while studying under his instructor, Takayama had the opportunity to measure chlorophyll fluorescence, and he then began to work to apply his research to the agriculture industry.

"At the time, machinery was very expensive, and the idea of applying my research to the agricultural field was dismissed as nonsense. But as the technology developed into the present day, consumer needs significantly changed, and the field became a real focus of attention. Even I was surprised," says Professor Takayama.

Smart agriculture and smart food chains are now the biggest topics for humanity, and are essential in achieving a sustainable society. Professor Takayama humbly dismisses his successes as being down to good timing, but perhaps it is more likely that his insights were key.

植物の生体情報を見える化して、未来の農業に役立てる

いま、日本の農業は転換期にある。ここ5年ほどで、高齢の農業従事者の離農が加速しており、今後、農業生産人口が急激に減少すると予測されているためだ。一方、中高年の健康志向を背景に、生鮮野菜へのニーズが高まっていることから、その安定供給が急務となっている。そこで注目されているのが、効率的かつ安定的な野菜の生産が可能な植物工場である。こうしたなか、高山弘太郎教授は、太陽光植物工場において、植物の生体情報をモニタリングし、取得したデータを解析することで、農業のスマート化に取り組む。すでに実用化されたシステムもあり、高山教授の挑戦に注目が集まっている。

ビジネスとして成立する「強い農業」のために

いつの時代においても、食の安定供給は最重要課題だが、家族経営が大多数を占める現状の日本の農業は、近い将来立ち行かなくなる、と高山教授は危機感を募らせる。そして、急激に進む農業生産人口の減少と、10年程度で大きく変わる消費者マインドの両方に対応するためには、生鮮野菜などを安定的に供給するための新たな農業生産システムの構築が欠かせない、と指摘する。

「その有力候補が植物工場です。10年ほど前なら、植物工場の野菜より、農家のおじさんの手作り野菜のほうがはるかに人気でしたが、いまや、安定供給が可能で、完全なトレーサビリティができる温室育ちの野菜は、品質が保証された安全・安心な食物として広く受け入れられています。中高年の健康志向を背景に、生鮮野菜へのニーズがこの十数年で1.5〜2倍に伸びていることもあり、今後はますます大規模な植物工場への依存が高まると考えられます。一方で、植物工場の運用にはそれなりの資本が必要であり、農業をビジネスとしてきちんと成立させる必要があります。そのためには、生産マネジメントが欠かせません。しかし従来は熟練者の経験と勘に頼ってきた部分が大きく、科学的なアプローチはほとんどなされていませんでした」と高山教授は言う。

もっとも、植物工場の環境制御の知見は20年ほど前に確立されていて、すでに世界中でコンピュータによる自動制御が行われている。しかし、その検証までは十分になされてこなかったのだという。そこで高山教授は、植物の生育状況をモニタリングし、もっともコストがかからない方法で環境調整をして、より最適な生産を実現しようとしているのだ。

「科学的なアプローチをすれば、生産性は必ず向上します。しかし、たとえば通常の温室栽培の4〜5倍の収穫量があったとしても、ビジネスとして成立しなければ意味がない。コストと利益のバランスを見ながら、最適な生産をすべきです。そのためにはまず、状態を測って、そのデータをもとに解析をして、最適な生産を見極める必要がある。それが可能になれば、市場で競争できる強い農業を実現できるでしょう」

植物の光合成を計測・診断して、生育環境をコントロールする

こうしたなか、高山教授が植物の生育状況を把握するために採用しているのが、画像による計測と解析である。その背景を、高山教授は次のように説明する。

「10年前なら100万円もしたようなCCDカメラが廉価になり、いまや同等の性能のカメラがスマートフォンに搭載されるようになり、画像解析もスマホ内蔵のコンピュータでできるようになりました。これにより、農業現場に画像解析技術を持ち込むことができるようになったのです」

とりわけ画期的なのが、植物の光合成活性を画像で捉える研究だ。世界に先駆けて、植物工場で光合成を自動計測できるロボットを開発して、2017年には井関農機が植物生育診断装置として販売を開始している。なお、植物工場は、LEDなどの人工光源を活用する人工光型植物工場と太陽光植物工場に大別されるが、高山教授は後者を対象としている。

「このロボットは、太陽光植物工場内を夜間に自動走行しながら、トマトの葉緑素、つまりクロロフィル(Chl)の蛍光画像を計測するものです。Chl蛍光とは、Chlが吸収した光エネルギーのうち、光合成に使われずに余ったエネルギーの一部が、赤色光として捨てられたものです。これを測るために、夜間にトマトの葉に青色LEDによる励起光を照射して、光合成反応系を人工的に刺激し、その際のChl蛍光の強度変化を測ります。Chl蛍光強度が時間とともに変化する現象は『インダクション現象』と呼ばれていて、これは私の恩師である大政謙次東京大学名誉教授により、1987年に世界で始めて画像計測されました。この蛍光強度の変化が、植物の光合成能力やストレスの影響を表すことから、植物の状態を知ることに役立つのです」

実際にこのロボットを使って、トマト3万本を育てる170m×76mの温室で計測してみたところ、場所によって光合成の活性にムラがあることがわかった。こうした解析結果をヒートマップで見える化することにより、水やりや温度などさまざまな環境条件をコントロールして、生育状況の改善に活用できる、というわけだ。

さまざまな新技術が農業に革新をもたらす

光合成の計測に関しては、リアルタイムのモニタリングシステムも手がけている。こちらは、栽培している植物を透明の筒状のビニール袋で包み、下部の開口部から流入する空気と、上部のファンから排出される空気のCO2濃度とH2Oの濃度差を計測することで、光合成の速度と蒸散速度を測るというものだ。安価なセンサで高精度に光合成と蒸散が計測できることから話題を呼び、2019年に豊橋技術科学大学大学発のベンチャーであるPLANT DATAと協和ハイポニカが共同で市販も始めた。引き合いも多く、農業先進国であるオランダからの問い合わせもあるという。

「光合成を促進させたいのならCO2濃度を高めれば良いわけですが、十分に光合成ができているのなら、わざわざCO2を投入する必要はなく、コストを抑えられます」と高山教授は説明する。

一方、より安価に、しかも従来型の小・中規模のビニールハウスにも導入できる、軽量の吊り下げ型の植物生体画像情報計測ロボットも提案していている。こちらはChl蛍光画像計測に加えて、カメラを上下に動かすことで、植物全体や詳細のカラー画像を捉えることが可能だ。取得した画像を深層学習で解析することで、生育の変化や、花や果実の自動検知ができるようになり、収穫時期や収穫量の予測にも役立てられるという。また、それらを直感的に理解できるように見える化した、ユーザー・インタフェイスの開発にも注力する。

「深層学習はじつに破壊的な技術で、これまでなら慎重に時間をかけて開発していた生育モデルの開発も解析も、あっという間にできてしまいます。日々の計測から大量のデータが集まれば、より精度を高めることもできる。深層学習によるAIは、これまでの農業を劇的に変える可能性があります」

さらに、学内の澤田和明教授らが開発した超高感度シリコンCMOS型イオンイメージングセンサを用いた超小型の匂いセンサを用いることで、植物のストレス状態を計測する研究開発にも取り組む。

「じつは植物同士は匂いでコミュニケーションをとっていて、その匂いを診断することで植物の調子がわかるんですね。これは2007年にオランダに留学していたときに学んだものですが、当時からは想像もできないほど、廉価に小型の装置を開発することができました。この匂いセンサを使えば、水が足りないとか、農薬が多すぎるといったアラームとしても使えます。まさに生産現場にフィットする、簡易なセンサとして活用されることを期待しています」

異常気象や災害の多い昨今、安定した値段で安心して食べられる野菜の供給は人々の願いだ。高山教授の成果が、これからの農業に革新をもたらすことに期待したい。

(取材・文=田井中麻都佳)

取材後記

もともと生物と物理が好きだったことから、大学では農学部へ進学して、農業機械や農業土木を学んだ高山教授。しかし、当時の研究対象は農業機械の耐久性などが主で、人気のない分野だったという。ただ、恩師の下でクロロフィル蛍光の計測と出合ったことがきっかけとなり、これを農業に応用したいと研究に励んだ。

「当時は機器が高額で、農業現場への応用などナンセンスだと怒られました。それがいまでは技術が進展し、消費者ニーズも大きく変化したことで、まさに注目の分野になった。自分でも驚いています」と高山教授は語る。

スマート農業やスマートフードチェーンは、いまや持続可能な社会の実現に欠かせない人類最大のテーマだ。高山教授はタイミングが良かっただけと謙遜するが、やはり先見の明があったのだろう。

Researcher Profile

Dr. Kotaro Takayama

Dr. Kotaro Takayama received his PhD degree in 2004 from The University of Tokyo, Japan. He started his carrier as a research assistant at Ehime University in 2004 and became an assistant professor there in 2007. From 2013 to 2017, he was an associate professor, and became a professor in 2017 there. He held a broad variety of positions including a guest researcher at Wageningen University and a part-time lecturer at Osaka Prefecture University and Yamaguchi University, respectively. He joined at Research Center for Agrotechnology and Biotechnology, Toyohashi University as a specially appointed professor in 2018. Now he is a professor at Electronics-Inspired Interdisciplinary Research Institute, Toyohashi University of Technology and Ehime University.

Reporter Profile

Madoka Tainaka is a freelance editor, writer and interpreter. She graduated in Law from Chuo University, Japan. She served as a chief editor of "Nature Interface" magazine, a committee for the promotion of Information and Science Technology at MEXT (Ministry of Education, Culture, Sports, Science and Technology).

ここでコンテンツ終わりです。