ここからコンテンツです。

Microhotplates for a smart gas sensor

Easy way of fabricating miniature hotplates By Tatsuya Iwata

Tatsuya Iwata and his colleagues have developed microhotplates (MHPs), in which an SU-8 photoresist was employed as a supporting material. The MHP can moderate the requirement for the layout design and the process condition of integrated smart gas sensors. Furthermore, the researchers confirmed that the MHP has a good thermal isolation property. It was demonstrated that the hotplate can be heated to 550 °C, and that it operates stably for 100 min.

Gas sensors used for leakage alerts and air quality monitoring are essential in our daily lives. As we move towards a society where they are becoming ubiquitous, smart gas sensors, which perform signal processing and communication besides sensing, are increasingly gaining attention. In addition, integrating these functions into a single chip leads to low-cost and miniature smart gas-sensing systems.

Semiconductor gas sensors, which are the most widely used gas sensors, require a sensor material to be heated to several hundreds of degree Celsius. Therefore, in order to integrate these gas sensors with electronic circuits, a micro-hotplate (MHP), which is a MEMS-based heating structure, is required to thermally isolate the sensor and the circuits. The MHP is generally mechanically unstable, and there exists a tradeoff between the mechanical stability and thermal isolation property.

Recently, a research team led by Assistant Professor , Tatsuya Iwata has proposed the employment of SU-8 as a supporting material for the MHP, in order to improve the mechanical stability, while maintaining the thermal isolation. Furthermore, SU-8 is a polymer material that is widely used for microelectromechanical systems (MEMS) and has good mechanical stability and low thermal conductivity. The researchers fabricated the MHP and investigated its heating characteristics.

The first author Assistant Professor, Tatsuya Iwata, said that "By using a thick polymer film, it is possible to simultaneously realize the properties of mechanical stability and high thermal isolation. Furthermore, although we have yet to fully evaluate the mechanical stability, this device appears to be promising for use in smart gas sensors."

"Mechanical stability is one of the major concerns for fabricating an MHP. Using a polymer material for such microhotplates seems to be an eccentric approach, but surprisingly, it went well. Moreover, this device will boost our study to develop multimodal sensors, which are multifunctional integrated sensors including gas sensors," said Professor Kazuaki Sawada.

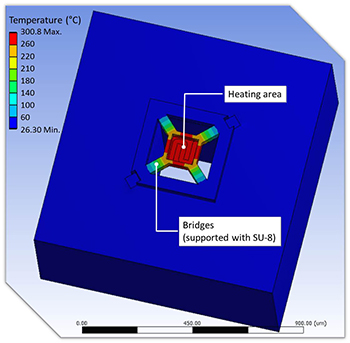

The fabricated MHP consists of a heating membrane with an area of 140 μm × 140 μm, and a 33-μm-thick SU-8 layer deposited on its bridges. The simulation confirmed that the MHP displayed good thermal isolation properties (Fig. 1). The MHP temperature was found to reach 550 °C at 5V. Moreover, the power consumption of the MHP approximately corresponded to 13.9 mW for heating to 300 °C, which is comparable with the power consumption reported in the previous studies. Furthermore, a stable operation under a constant voltage was observed for 100 min.

Owing to the thick SU-8 layer, the MHP does not need strict control of the stress that occurs inside the membrane during the fabrication process. This feature, together with the good thermal isolation property, facilitates the flexible layout design of the chip, and therefore, the MHP is beneficial to a miniature smart gas sensor chip. The researchers will advance their study to realize such smart gas sensors.

These research results were reported in the Journal of Micromechanics and Microengineering, on January 11, 2017.

Funding agency: Japan Society for Promotion of Science, Grant-in-Aid for Young Scientists (B), Grant Number 15K18049

Reference

T. Iwata, W. P. C. Soo, K. Matsuda, K. Takahashi, M. Ishida, and K. Sawada (2017), Design, fabrication, and characterization of bridge-type microhotplates with an SU-8 supporting layer for a smart gas sensing system, J. Micromechanics Microengineering, 27(2), 24003.

https://doi.org/10.1088/1361-6439/aa556b

スマートガスセンサ向けマイクロホットプレート

岩田達哉助教たちは高分子材料であるSU-8を用いてマイクロホットプレート(MHP)を作製しました。このMHPを用いることでスマートガスセンサのレイアウト設計やプロセス条件に対する技術要求を緩和することができます。彼らはそのMHPが優れた熱分離性能を有することをシミュレーションにより確かめ、また550°Cまで加熱が可能であることと、少なくとも100分間の安定動作を実証しました。

ガスセンサはガス漏れ検知や空気質モニタリング等に用いられ、我々の生活に不可欠なものです。一方、近年ユビキタス社会実現へ向け、センシングに加え、信号処理や情報通信の機能を有する、いわゆるスマートガスセンサが注目を集め、盛んに開発が行われています。さらに、これをICチップ上に実現することで、スマートガスセンシングシステムの低コスト化や小型化が可能となります。

現在最も普及している半導体ガスセンサは、その材料を数100°Cに加熱する必要があります。そのため、これを電子回路と集積化するには、回路との熱分離のため、微小電子機械システム(MEMS)技術を用いたマイクロホットプレート(MHP)が必要となります。しかしながら、このMHPはその支持部が機械的に脆弱であり、強度を向上させると熱分離性能が低下してしまうというトレードオフが存在します。

そこで、岩田助教率いる研究チームは、機械的強度と熱分離性能の両立をめざし、SU-8をMHP支持部の補強材料として用いることを提案しました。SU-8はMEMS構造体に広く用いられる高分子材料で、その特徴として、良好な機械的強度と低い熱伝導率が挙げられます。研究チームは提案のMHPを作製しその加熱性能を評価しました。

筆頭著者の岩田助教は「厚い高分子膜を用いることで、高い機械的強度と熱分離性能を両立できます。機械的強度に関しては今後評価する必要がありますが、これはスマートガスセンサに向けた有望なデバイスであると考えています。」と述べています。

「高い機械的強度を得ることはMHP作製の上での大きな課題の一つです。(一般に熱に弱い)高分子材料をこのようなMHPに用いることは一見非常識な発想ですが、思いのほかうまくいきました。このデバイスによって、我々の目指すマルチモーダルセンサ(複数のセンサを1チップ上に集積化した高機能センサ)の開発も大きく前進するはずです。」と澤田教授は述べています.

作製されたMHPは約140 μm四方の加熱領域を有し、支持部であるブリッジ上に膜厚33 μmのSU-8層が形成されています。シミュレーションにより、本構造は良好な熱分離性能を有することが確認され(図1)、駆動電圧5 Vにおいて550°Cまで加熱可能であることが実証されました。また、消費電力は300°C加熱時に約13.9 mWと、これまでに報告されているMHPと同程度の低消費電力を達成し、少なくとも100分間の安定動作も示されました。

このMHPは、厚いSU-8を形成しており、作製時に材料内部に発生する力(残留応力)の精密な制御が不要となります。この特徴と良好な熱分離性能のおかげで、スマートガスセンサはより柔軟なレイアウト設計が可能となり、その小型化につながります。研究者らはこのようなスマートガスセンサ実現に向け、引き続き研究を進めていきます。

本研究成果は平成29年1月11日付で、Journal of Micromechanics and Microengineering のオンライン版に掲載されました。

本研究は、日本学術振興会 科研費 若手研究(B)、15K18049の助成を受けて行われました。

Researcher Profile

| Name | Tatsuya Iwata |

|---|---|

| Affiliation | Department of Electrical and Electronic Information Engineering |

| Title | Assistant Professor |

| Fields of Research | Semiconductor devices |

ここでコンテンツ終わりです。